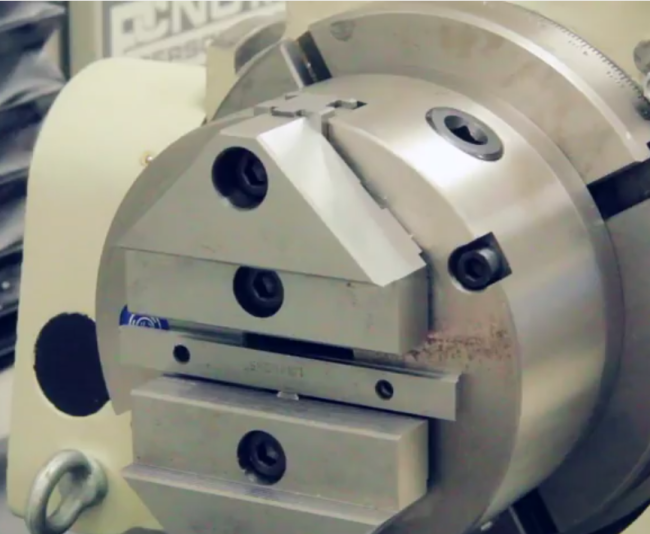

Although not nearly as common as 3- or 4- Jaw chucks, a 2-Jaw Chuck can be quite handy for certain 4th Axis jobs. The jaws on a 2-Jaw chuck are opposite each other (obviously!) and they are driven by a scroll plate, just like the jaws on a 3-Jaw chuck. They are typically used in 2 scenarios:

- Rapid Prototyping - for example, cutting a 3D shape out of a block of plastic or wood with a single 4th axis operation using a ball end mill.

- Holding odd parts - In this case, they are often used with custom soft jaws milled for that purpose

Here's a quick video with Mike C. demonstrating some setup basics when using a 2-Jaw Chuck:

We have 2 Jaw Chuck kits available for both 6" and 8" Tormach 4th Axis models:

More Tormach Fab Lab Videos:

- How to Setup a 3-Jaw Chuck on a 4th Axis

- How to Setup a 4-Jaw Chuck on a 4th Axis

- Toolmaker Vises Tips

- How to use a Coaxial Indicator

- Fixture Plate Basics

- Getting Started with Tension/Compression Tapping

- Getting Started with Auto-Reversing Tapping

- How to Swing Indicate a Square

- How to Swing Indicate a Circle

- How to Bore an OD

- How to Bore an ID

- How to Use a Sine Vise

- Tips for using Strap Clamps

- How to Square a Block