Aluminum is often the first metal that new machinists experience, and rightfully so. Its versatile, economical, and forgiving when it comes to feeds and speeds. But all those pluses come with a few compromises as well. So, here’s our list of four things everybody hates about aluminum.

4 - Easy Peen

Aluminum is soft, which is why it’s so easy when it comes to cutting, but being such a soft metal means it can peen quite easily. If you have a finished part in aluminum, there’s nothing worse than dropping it or nicking it on a tool and suddenly, your finished part is no longer so finished.

3 - Welding

While aluminum is softer and lighter, which makes it easier to handle, welding aluminum presents a whole different challenge. Some would argue that welding aluminum isn’t difficult, it’s just different. True, but still different enough to make this list. Aluminum joints solidify faster because it has a high thermal conductivity and melts at a much lower temperature than steel, which could be considered an advantage. But, aluminum is often covered with a “skin” of aluminum oxide, which melts at a much higher temperature than steel. Obviously, this can cause some challenges if proper preparation isn’t considered.

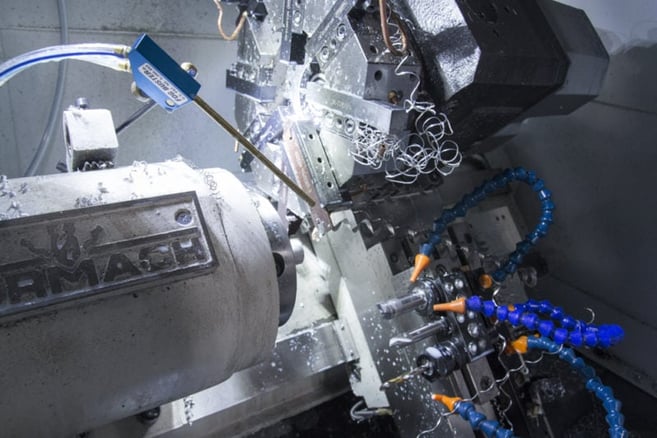

2 - Stringy Chips

When it comes to turning aluminum, it can be challenging to get decent chip breakage. This leads to a stringy birds-nest of chips on the lathe, and which can clog up your cutting tool and scratch the surface finish of the part. You can mitigate this by choosing inserts designed for aluminum and make sure to take a deep enough cut to activate the chipbreaker.

1 - Clogged Flutes

Similar to the challenge of stringy chips, aluminum has been known to clog up the flutes of cutters. Aluminum is so soft that if you’re cutting dry or taking heavy cuts, the flutes can get quickly jammed with chips. For Tormach videos, we often cut aluminum dry to help keep the cutting visible, but we generally recommend using a Fog Buster or flood coolant to clear chips and lubricate the cutting edge of the tool as it is more forgiving to the cutting parameters. Use 2-flute or 3-flute cutters (instead of 4 flute) for aluminum as the larger chip pockets provide necessary room for chip removal.

Not All Bad

While aluminum has some drawbacks, it is quite a versatile metal, and it’s extremely forgiving when it comes to tool wear and feed rates. In fact, Jason Pulvermacher, a Tormach machinist, said, “[Aluminum] is the easiest thing in the world to work with.” As with anything in the world of manufacturing and engineering, there’s always a compromise – a few minor challenges aside, aluminum is inexpensive and quite forgiving, making it one of the best metals to start cutting.