I know what you’re thinking. Why should you bother milling everyday, boring plastics when you have a Tormach mill or lathe that can cut any metal you can imagine?

Plastics aren’t as simple as they seem, and machining them can be worth the time away from mild steel and aluminum. So, here are 6 reasons why you should try machining plastic.

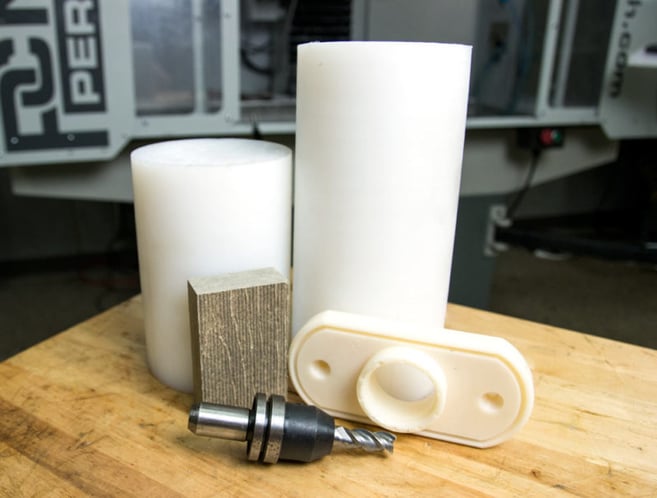

Plastic Is Cheap

Aluminum is definitely cheap, but if you’re learning, experimenting, or just want to try new cutting methodologies, plastic provides another inexpensive route. Many plastics can get pricier, especially when you’re dealing with the high-end stuff, like Peek or Vespel, but the more common plastics are on the low-end and easy to find, like ABS and Delrin.

Read: The Truth About Titanium

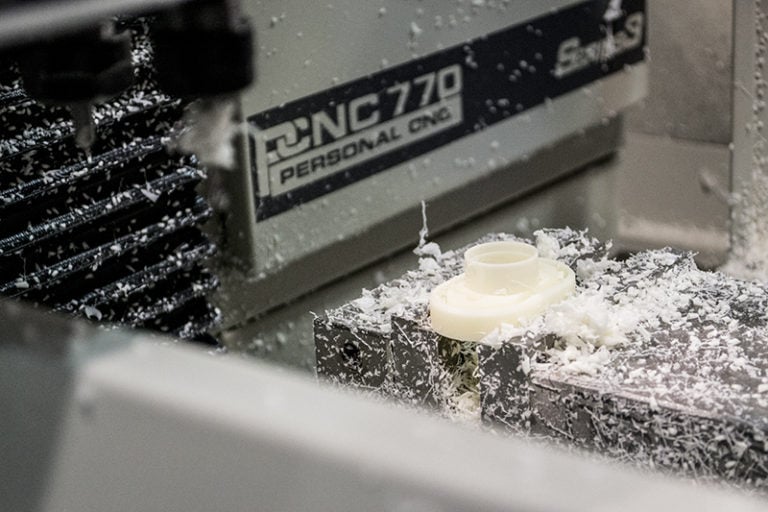

Plastic Is Forgiving

While you can still break a few tools while machining plastic, it is far more forgiving than metals and alloys. Because of this, you are far more likely to break the inexpensive plastic stock than you are to break a tool.

Feeds, Speeds, and Heat

When machining with metals, heat can sometimes be an issue that causes chips to weld themselves onto your cutter or your part – a recipe for cruddy surface finishes and lots of broken cutters. Plastics have a much lower melting point than metals, so lower RPMs and higher feeds are often optimal – lower spindle speeds cause less friction, while higher feeds keep the tool moving, preventing unwanted melting.

Still Make Good Parts

While we are all fond of metal, plastic parts have their place and sometimes, are preferred over metal parts. The ease of use and cost with plastic makes it ideal for prototyping, but some applications require plastic parts – FDA regulated parts, medical device applications, etc.

Light-Weight

When designing or creating an assembly, many different factors have to be calculated and compromised. Oftentimes, the overall weight of a part assembly is a crucial element to design. Even the lightest of metals are upwards of two and a half times the weight of most plastics. While metal is often stronger, using plastic in an assembly might be all that’s necessary.

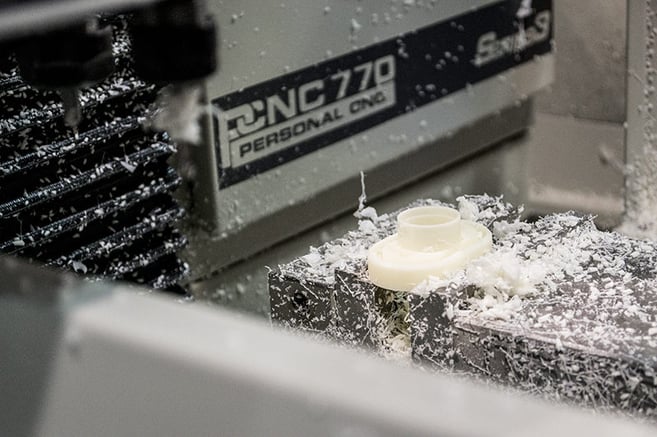

Making You a Better Machinist

Inconsistencies from section to section of plastics are incredibly common, meaning that you have to think about the material a bit differently than metals. Plastic may be soft and forgiving, it still requires close attention to feeds and speeds to get a decent finish and accurate parts.