Sometimes, there can be a lot to CNC machining – everything from computer programming to materials science is involved – but paying attention to a few things can make a big difference in the parts that you make. Here are six little things that can make a big difference with your CNC machining.

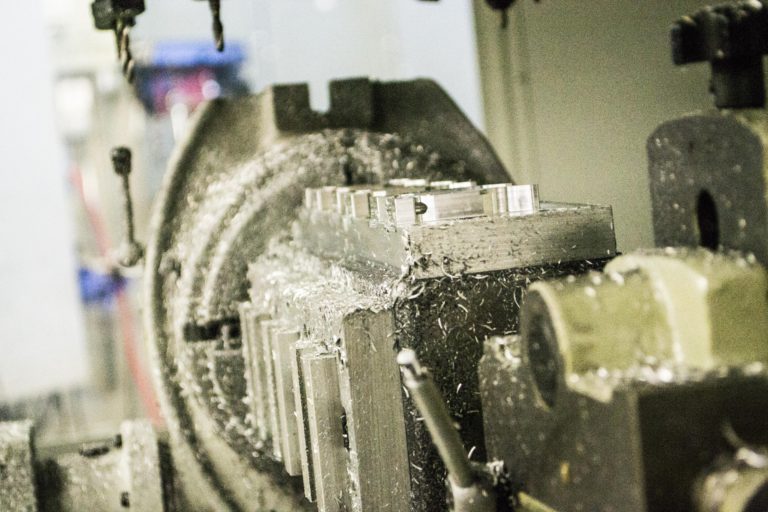

A clean machine is a happy machine.

While making chips is what we all love about metalworking, cleaning those chips out of your machine is vital to keeping things running smooth. Stray chips can cause workholding to be imprecise, or worse, not hold at all. Piled chips can also cause premature wear and tear on vital components of your CNC machine and its components.

A Haimer will change how you use your CNC machine

The Haimer is a German-made edge finder that allows for fast and precise locating of edges and surfaces in all three axes (X,Y, and Z). Some folks opt for a lower-cost option when they first start CNC machining, but owners of a Haimer Zero Master will tell you that it is one of the best tools they purchased for their mill. That being said, it’s important to learn the basics of measurement and edge finding. But, once you have wrapped your head around the concept, a Haimer is the way to an easier CNC machining lifestyle.

Don’t be afraid to crash your CNC machine.

Here at Tormach, we don’t want to recommend that you crash your CNC machine, but you can’t be afraid of it either. Tormach machines are made to be robust and we do our best to make components inexpensive to repair in case the worst does happen, so crashing a machine doesn’t cause quite so many tears. If you’re afraid of crashing, you’ll never be able to fully grasp the capabilities of CNC. The glory of having a mill controlled with a computer is that you can get quite close to areas you don’t want to machine without ruining them; you can cut quite thin walls and floors; and you can create some truly unique 3D shapes. But, you can’t be too conservative and fearful of a machine crash, otherwise you’ll never see some of the coolness that CNC offers.

Don’t be afraid to be aggressive - it's a great way to learn CNC

Much like crashing a machine, being aggressive with your speeds and feeds can lead to some nasty results, but learning by being aggressive with your numbers will help develop that elusive understanding of feeds and speeds. When you know the limits of your CNC machine in various materials and with different tooling, it will help you make more educated cuts.

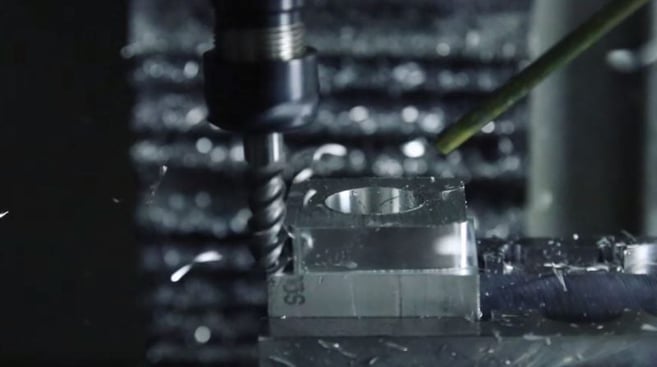

Choose the right cutters.

I’m as big a fan TiCN coatings as the next guy, but to make quality parts, you need to pick the right cutters for the materials and types of CNC cuts you’re going to make. Different cutters can have different geometries, are made from a variety of alloy materials, and have a million different coatings that can all be specific to certain types of cutting. Do your research before buying a new face mill, because it might just sit in the tool box once you see it cut.

Adjust your toolpaths – trust your CAM, but not always.

Making tweaks to CNC toolpaths is an art, and not something that is easily learned or taught. There are millions of different ways to cut the same part, but they aren’t all going to provide the best finish or the fastest process. Experimenting and tweaking toolpaths is vital to becoming a better machinist. Utilize everything that CAM can provide, but don’t always rely on the auto-populated cutting paths. Make adjustments and see what happens and you’ll get to know your machine like a true artisan machinist. What to read next: 6 Go-To Resources to Make You a Better Machinist