Most routers are designed to work on larger, flat work - think MDF board and the like. Routers are generally less rigid than mills of the same size, and the real advantage emerges with scale. That’s why Tormach created the 24R Router - to provide a router with the more robust capabilities of industrial scale routers without breaking the bank.

Rigidity You Didn’t Realize a Router Needed

Not all machines are created equally. The key is choosing the right machine for the job and your situation. Smaller routers on the market are great for education and dipping your toe into router work, but if you’re looking to make money with your router, your needs change.

A more rigid machine means you can move faster and make chips more efficiently. Having a more rigid machine means that, although most owners will still use their 24R routers to cut a majority of plastics and woods, you're open to materials beyond those. For instance, NYC CNC used their 24R Router to cut aluminum and even steel.

Like many of our other machines, Tormach’s goal with the router was to provide accessible tools that can do real work. With the accessibility of PathPilot as an intuitive, easy-to-learn control system and an approachable price, the 24R Router is for those who are ready to start taking their routing work a little more seriously.

A Router Built for Business

The 2 ft X 4 ft format is a standard material size in many industries, which makes it easy to start cutting larger work. The size of the 24R Router also allows Tormach to provide the machine on a welded stand with a cast iron base that can be delivered on a lift truck (like all our other machines).

The travel of the X- and Y-axes are actually slightly larger than 2 ft X 4 ft, which means you can hit every angle on a standard 2 ft X 4 ft piece of material. The extra Y travel also allows for end-of-table machining, making the creation of finger or dovetail joints possible.

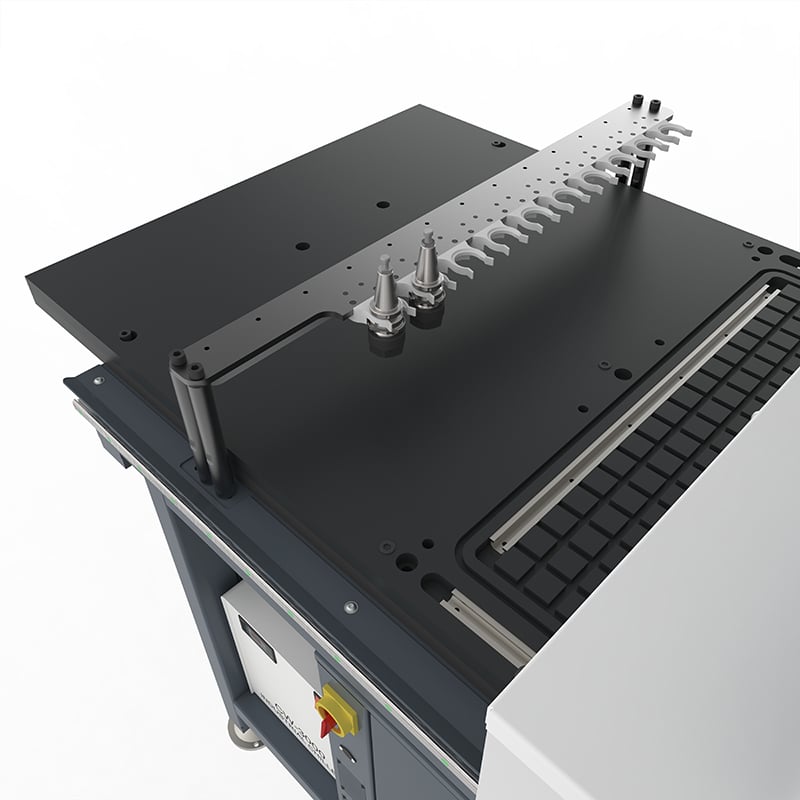

And now, we’ve announced a new accessory that will help take automation of your cutting to a new level - the 24R Router Automatic Tool Changer (ATC).

Adding an ATC to your setup not only streamlines the process of changing tools, but it allows you to step away from the machine while it’s cutting. The 24R Router comes standard with an ER20 spindle

The ATC can hold up to ten tools and the kit includes an ISO20 spindle to upgrade from the standard ER20 spindle that comes with the 24R Router. This also includes a built-in power drawbar and seamless integration with an electronic tool setter. That means that you don't have to measure tools each time you put them in the spindle - instead, tools are measured with their ISO20 holders and can be repeatably mounted to the spindle with ease.

The ATC also features repeatable tool lengths, which provides faster tool changes. The new lifting dust shoe feature allows you to check the router’s cutting action while the machine is running and leading into a cut.

Like our mills, if you’ve already purchased a router from Tormach, you can easily add the ATC after the fact. With the new availability of the ATC, the 24R Router has the speed and rigidity to help any business grow, whether you’re a woodworker or looking to dabble in other materials.