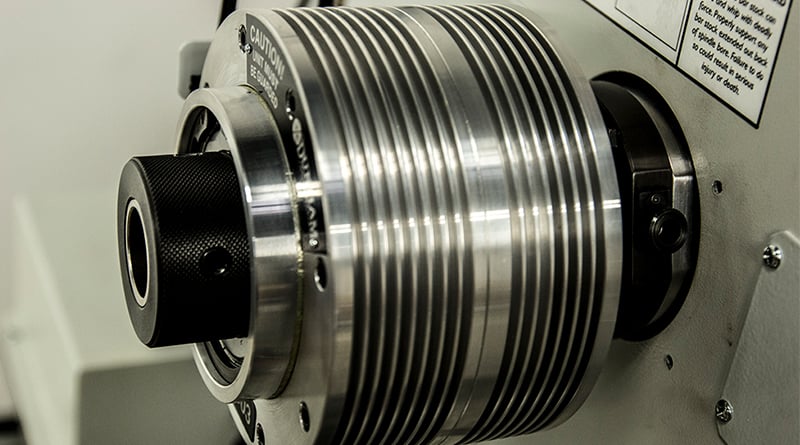

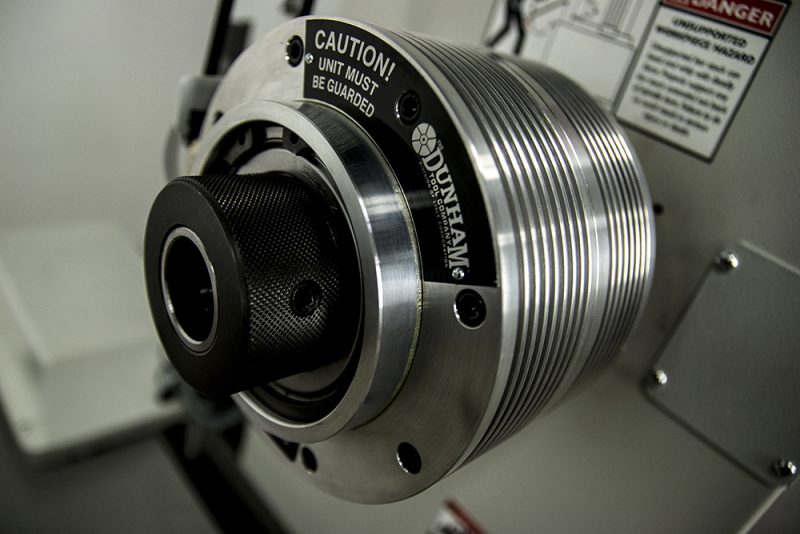

In the world of CNC, automation is important. Using CNC, we can make all sorts of products, widgets, and parts quickly and consistently, but we can streamline that process even more by adding automation. While CNC allows the production of complex parts and organic shapes with your mill or lathe, it also gives you the ability to cut parts without touching the machine. Hit Cycle Start and your part(s) are ready in short order. On a mill equipped with an automatic tool changer, you can set up your workholding to produce a large number of parts without having to go back to your machine. But on a lathe with a turret or gang tooling, that automation is restricted by your stock, unless you have a method to pull more raw material into the machine between cycles. We’ve addressed both issues with our new Automatic Collet Closer for the 15L Slant-PRO lathe, and a self-adjusting bar puller! A traditional lathe collet closer is a lever-actuated unit which you use to manually open and close the collet mechanism holding your work.

Our automatic collet closer is controlled through the PathPilot interface, which means the control system can open and close the collet for you. During a program, you can add a program stop to pause the lathe and switch out stock, or switch sides of the stock for different ops. With this automatic collet closer system, adjusting clamping pressure becomes much easier, too. By simply adjusting the regulator, you can refine the clamping pressure on your part and keep it consistent.

To fully automate a program, add a bar puller. With a bar puller, you can add an operation in your program to cut off a part, grab the stock, pull it to a designated length, and continue cutting parts. Not only does this allow you to make more parts without ever touching the machine, it can improve your cycle times. Save production time and improve repeatability with the Automatic Collet Closer for 15L Slant-PRO lathe paired with a bar puller. Both are available now!