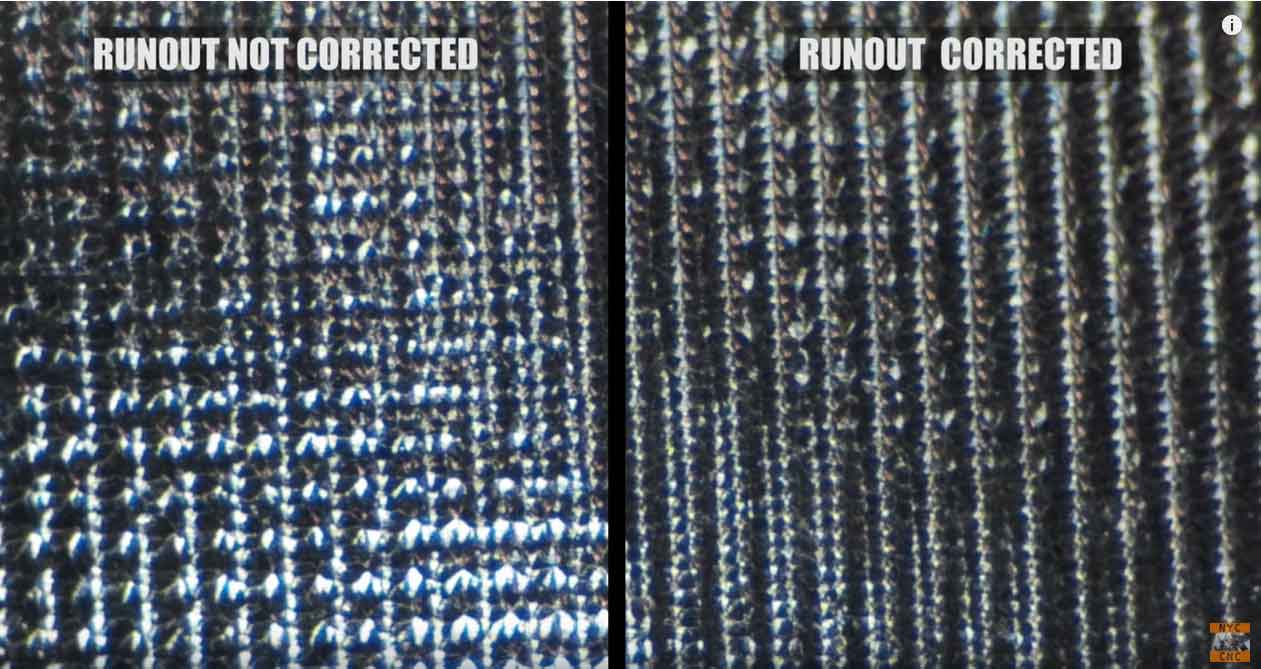

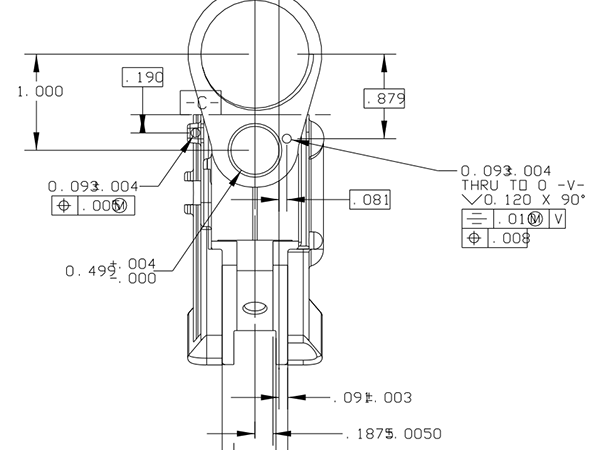

Incorrect speeds and feeds are a surefire way to make terrible noises, break tools, and scrap parts. Initial attempts to machine this hardened ring gear made noises that would make any machinist shudder. Through experimentation, we optimized a recipe that is reliable, leaves a great surface finish, and provides good tool life.