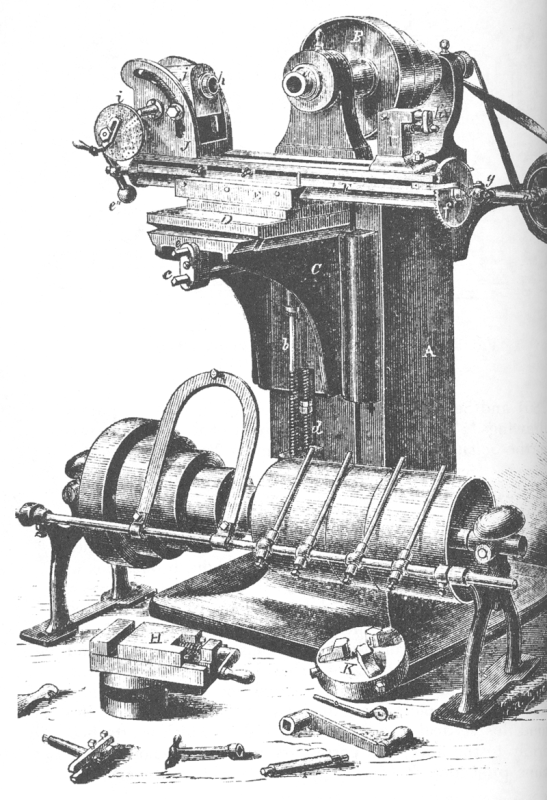

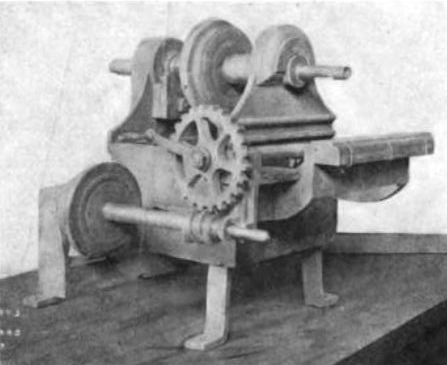

Manual machining has been around since two-man lathes in 1300 BCE. While the history of milling machines is a little foggy, some historians credit the first motorized milling machine to Eli Whitney, while others claim other inventors like Captain John H. Hall of the Harpers Ferry Armory, Simeon North, Roswell Lee, Robert Johnson, and Thomas Blanchard.

The knee-and-column vertical mill, often known as a Bridgeport-style manual mill, was first manufactured in 1938. Shortly thereafter, in the ‘40s and ‘50s, numerical control was introduced to automate machine tools based on programmable logic.

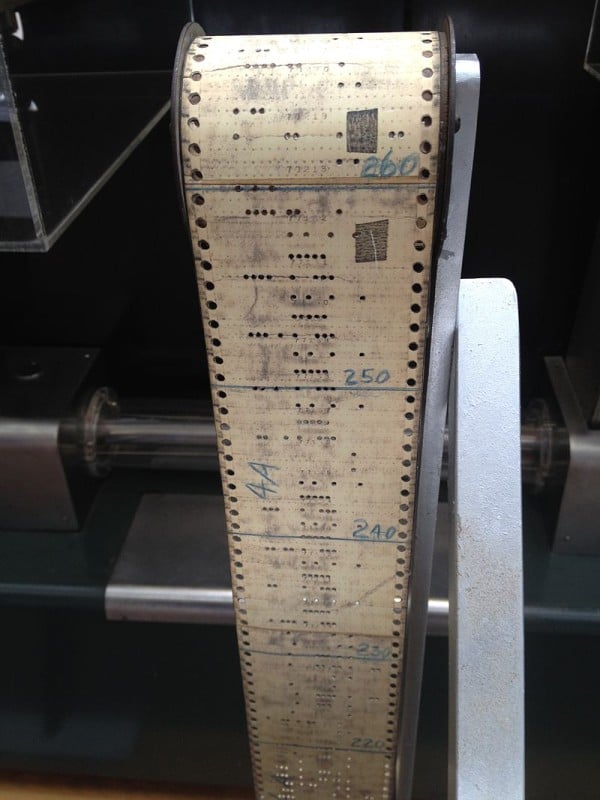

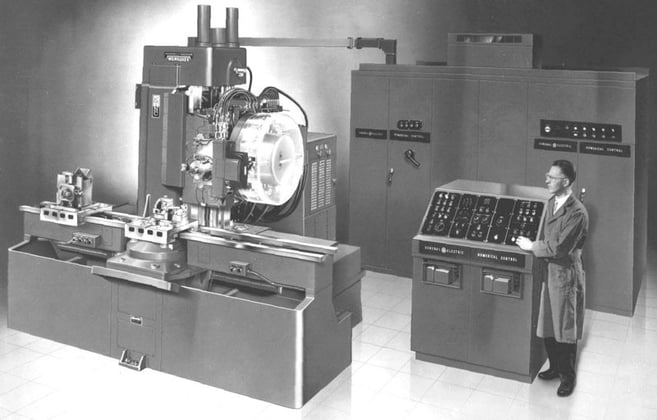

Users started converting manual machine tools to numerical control (NC) by using motors that moved the turn-handles based on a punched tape system. Shortly after, these mechanisms were augmented with analog and, eventually, digital computers, creating the first computer numerical controlled (CNC) machines.

Moving Away from Manual

G-code eventually replaced the punched tape system as machines advanced. Standard G-code was originally used in the MIT Servomechanisms Laboratory in 1958, and was later standardized by the Electronic Industry Alliance.

Computer-aided design (CAD) emerged during the ‘60s to give designers the opportunity to visualize their creations before a physical prototype was available. CAD and computer-aided manufacturing (CAM) have been almost synonymous since their inception, since getting a design into G-code for CNC operation requires details that CAM systems provide.

What Does CNC Mean for Fabrication?

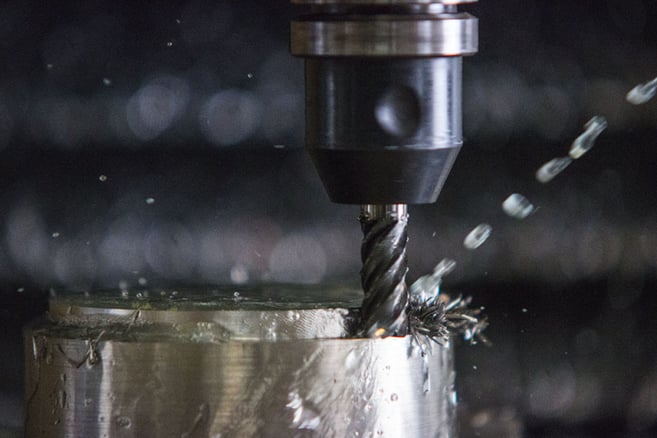

The obvious answer is that it automates the process of cranking turn-handles for hours on end to create parts. But beyond helping to eliminate tedium, CNC allowed engineers to add elements to their designs that had previously been unavailable. While it’s possible to cut curves and complex shapes with a manual mill, using CNC allows a user to make those shapes with great precision and consistency.

This changed the way parts were designed, and in the end, helped create more efficient and cost-effective components.

The Future of CNC

While CNC machining has a long, rich history, designs are only getting more complex and more customized as access to CAD has become much easier. As the barrier of entry to designing parts has become easier, there have been few simplifications to the process of fabrication (CAM, G-code, milling, etc.).

The future of CNC is certainly broad, but lowering the barrier of entry into it will be vital to helping the world of fabrication and invention grow - that’s why Tormach aims to keep our machines both capable and approachable.