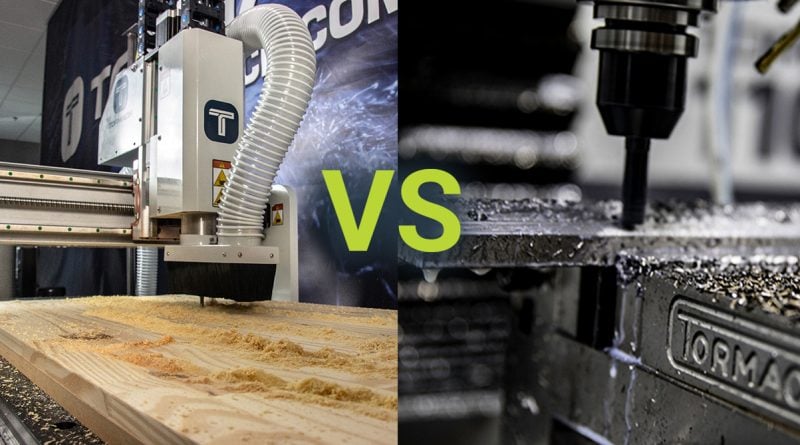

Users of CNC mill and CNC routers speak a similar language. Both are well aware of the challenges that finding the right speeds and feeds recipes entails, the obsession over finding new tools, and using CAM to make parts come to life.

To the veteran machine user, the differences between a CNC mill and a CNC router, but to the untrained user, it’s hard to define what sets them apart.

The main difference between a mill and a router is the axis motion. A router has a stationary workpiece and a spindle that moves in X, Y, and Z. While on a mill, the part moves in X and Y, and the spindle moves in Z.

Routers also typically use a gantry frame design, while most mills use a C-frame structure with a column and base.

These specific elements lead to certain advantages to each machine.

Why You Need a CNC Mill

CNC mills, like the 770M or the 1100MX, are designed to be more robust so they can handle harder materials like steel, cast iron, or titanium. While a mill can cut wood and plastics, the work envelope is limited in comparison to a router. A smaller work envelope means that there is more mass in a smaller space, which allows a mill to be more rigid than a router.

This smaller envelope and rigidity also allows for more accurate parts. So, if you’re looking to stay within a certain tolerance, a mill could be the right solution.

Mills usually have spindles that are lower speed, but higher torque, than a router. That’s another reason why a mill is better at harder materials… there’s a little more power to the cut.

Why You Need a CNC Router

Routers, like Tormach’s 24R CNC Router, are designed for larger parts, often cut from sheet materials. Because of their larger - often gantry-style - format, routers are often less rigid than their mill counterparts.

Being less rigid means most routers can’t cut things like steel or titanium, but rather, they are specifically designed to cut wood, plastics, foam, and even aluminum. This also means they leverage higher speed spindles, with speeds between 10,000 - 24,000 RPM (sometimes even higher).

The 24R was designed to fit a 2’x4’ sheet of material within the work envelope. That means that you can even cut the edges of a 2’x4’ piece of plywood without having to index the part.

Why You Need Both

A mill and a router are both valuable pieces of equipment. With their specific uses, it might seem easy to see which is the right machine for you.

But, having both changes the capabilities of your shop.

Typical shops with a router are making signs, cabinets and drawer fronts, wood carvings, or large-scale plastic components, while shops with mills are often making smaller parts that are components of a larger machine or other assembled products.

With both in your shop, you have the ability to do both large format work AND the small intricate components. You could machine out the components for a light-weight chassis on the router, and then cut the more robust and intricate components on the mill.

There really is an advantage to having both in your shop, but as always, it comes down to having the right tool for the job.