Cutting threads is an important element of machining. Even if you aren’t into making your own, custom-sized threads, it still helps to know how to create them. We’ve seen customers get pretty creative with their machines and cutting methods, but with a Tormach mill, there are three main ways to cut threads.

Old Fashioned Way – Mill-Turn Method

This method hearkens back to the old-school way of cutting threads with a manual machine. Basically, you mount the stock into your spindle and secure a lathe tool in your vise. Manually face off the stock to the desired size, and then use a die to create the threads by hand. The process isn’t easy and it’s kind of tedious, but if you need threads made, this is a quick and dirty method.

Thread Milling

A much more contemporary way to cut threads is by chucking up your stock in a vise (preferably a piece of hex stock) and cut it to the diameter of your thread. Once you have the portion of stock round and cut to the proper diameter, you use a thread mill and PathPilot’s conversational programming to create precise threads. This way, you can develop threads at the exact pitch and size that you are looking to achieve.

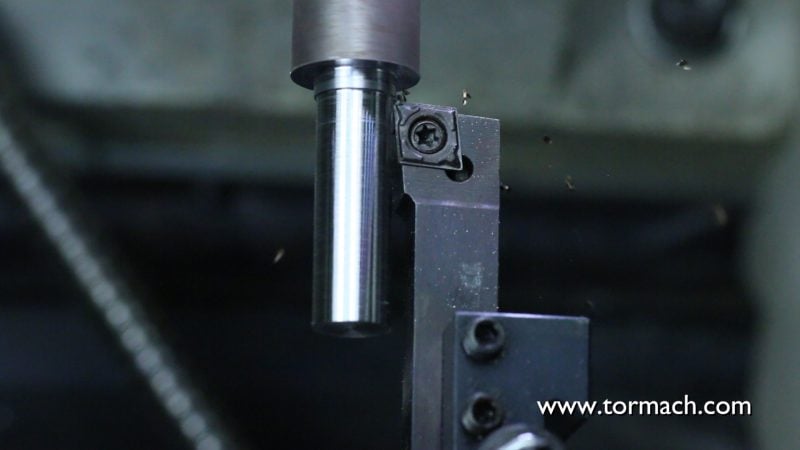

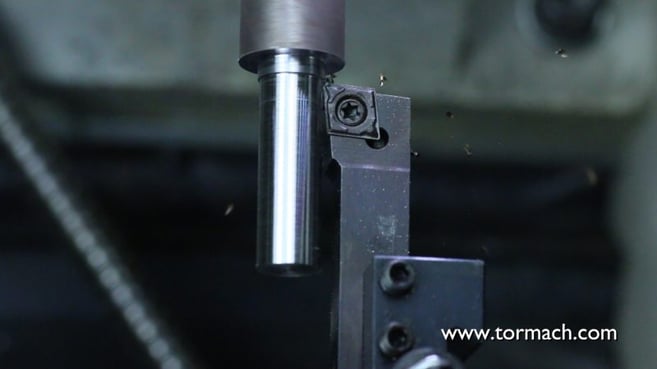

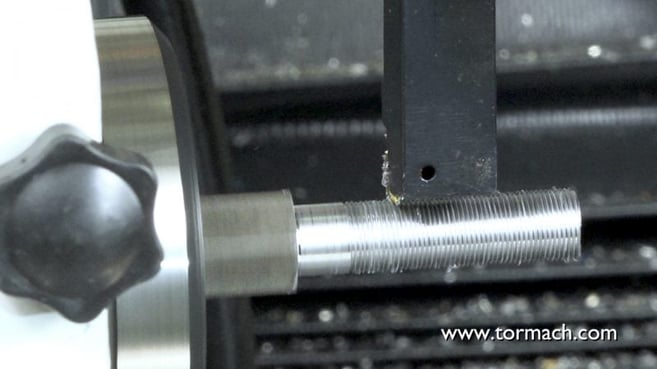

Turning on Your Mill

Using Tormach’s RapidTurn accessory, you have a small lathe right on the table of your mill. Similar to the old-fashioned method, you cut a piece of stock to the diameter of your thread with a standard turning tool. The difference comes when you can really utilize CNC. Using a single-point insert, you can use PathPilot conversational to create very precise threads quite quickly. This method can be a bit more complicated as you have to compensate for the tool tip, but once things are set up, the turning is the fastest way to get precise threads. Read: Tool Centerline Tolerances for Turning