Picking out the right drill can be challenging for novices like myself, especially when you take into account the material, flutes, coatings, point styles, tolerances, length, and other factors. But one of the first hang ups I encounter are the different types of sizes – letter sizes (A-Z), wire gauge (#s), fractional sizes (inches), and metric sizes (mm). My knee jerk reaction is to buy a handful about the size I need, labels aside. What’s with all these different systems anyway? Aren’t they just the same tool called a bunch of different names? Here’s what I learned.

Why are there different types of drill measurement systems?

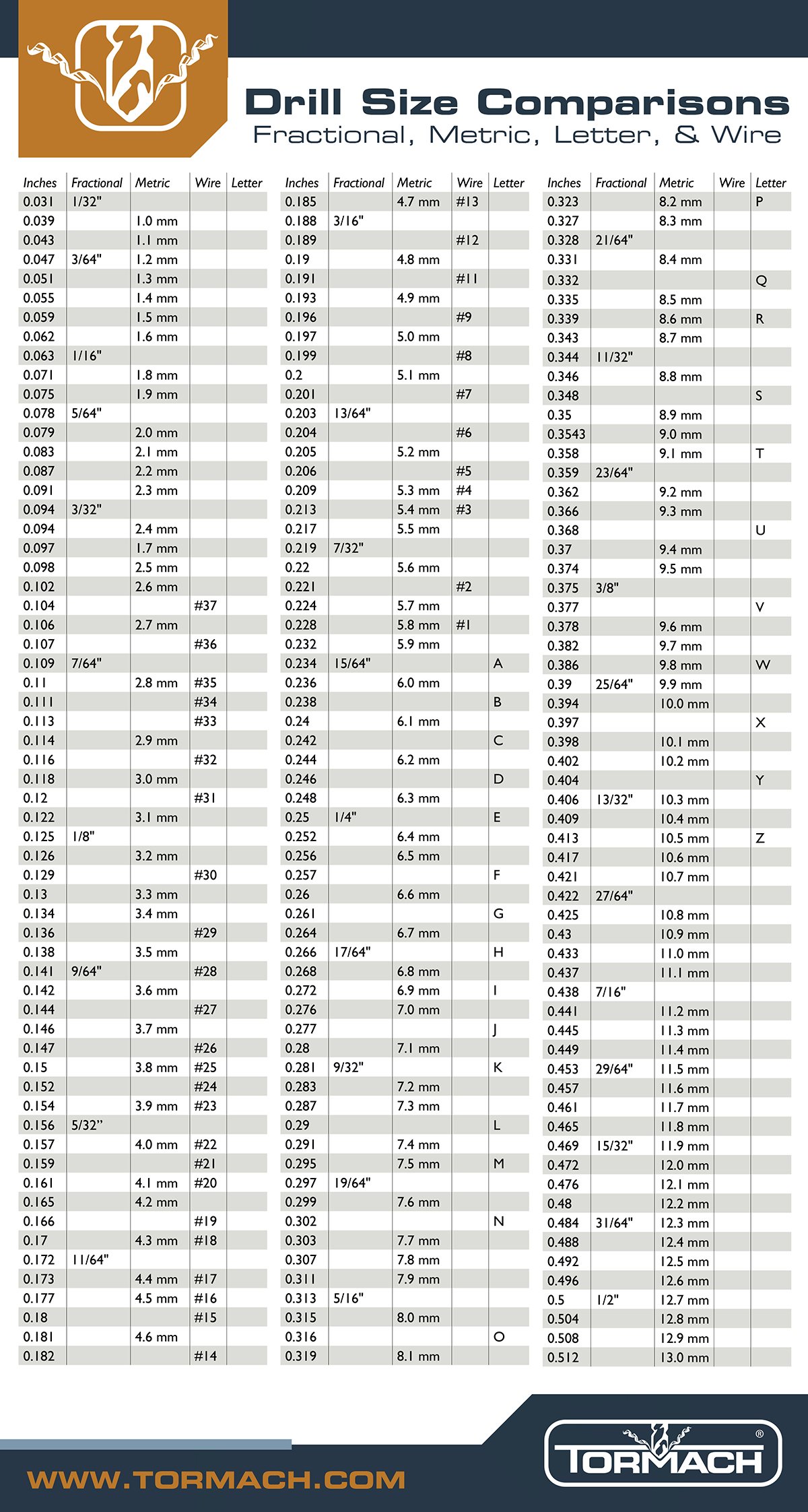

It turns out, the reason for letter, wire, fractional, and metric sizes is part historical and part association standardization. First, note that these sizes describe the tool diameter.

Fractional sizes were the product of the United States’ imperial measuring system, standardized by ANSI. These drills are available in 1/64” increments from 1/64” to 1”. You might see some drills as big as 1 3/4” inch, and those would have Morse taper shanks. Again, those are available in 1/64” increments.

Metric drill sizes are standardized by ISO, and are typically available in 0.1 mm increments.

Wire gauge drills were adopted by the United States from Europe, where the measurement referenced a wire’s diameter; since gauge can be defined as size, it’s literally, wire sized drills. These drills are available from #97, the smallest, to #1, the largest.

Letter gauges start nearly right after the wire gauge drills end in size, and get larger, spanning the entire alphabet.

Are the drills all the same sizes, just called different names?

No. The answer should have been obvious to me, but I felt better once I realize how much overlap there was and how close in size they could be. A Tap/Drill chart is a handy reference to help with this. Here’s an abbreviated table, or you can buy a comprehensive version HERE.

If you’re looking for more specifics on what drills to use when and how all these sizes fit into your project, my machinist coworkers said to look at the Machinery’s Handbook.

They also reminded me that, just like anything in machining, science only goes so far. There is an art to it you’ll only figure out one way – making chips.