Matt Pyle is a student at Buffalo State University in New York. Though he has had some shop experience while getting his Associates Degree in mechanical engineering technology, he is mostly self-taught when it comes to machine operation.

Before getting his Tormach PCNC 1100 and his 15L Slant-PRO lathe, Pyle started with a small, desktop mill and lathe. “There is absolutely no way I could even come close to what I am doing now with the equipment I used to have. I have grown more than I could have imagined with the two Tormach machines,” he explains. “My expectations of the equipment were blown away and then some – I am holding +- 0.0005 tolerances on a number of tiny parts that I make.”

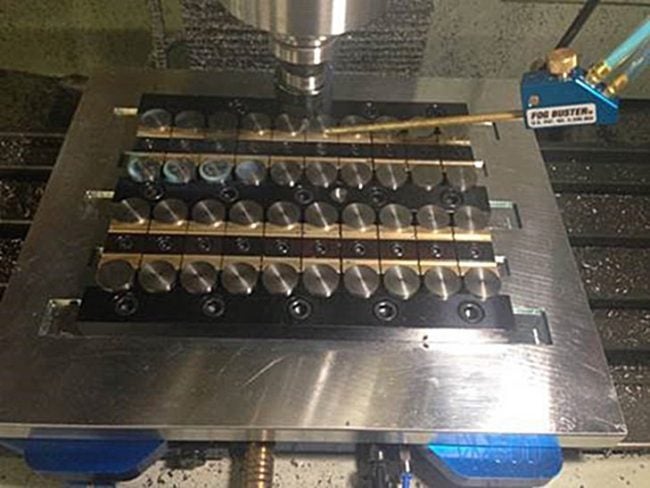

Pyle currently uses his Slant-PRO to do production of a stainless steel cup – producing 300 to 500 parts a week. “The 15L SlantPro is step one of about 15 steps the cups take to be a finished part.” He also uses the lathe to produce jewelry, as part of the process for lost wax casting, as well as custom mandrels for making jump rings.

“Robotics is also a hobby, when I am not running production parts,” he explains. “I have designed and built a gantry style pick and place machine that I am now using in production work, and I am hoping that I will be able to sell it as a low-cost open-source kit in the near future. There are too many other small jobs that I have done on both the lathe and mill to list.”

Pyle is also the captain of the Buffalo State Mini Baja Team for a competition held by SAE International. He plans to use both his Tormach mill and lathe to develop parts in the coming months of competition.

Pyle: “we are looking at machining a new gearbox. While we have access to state of the art equipment at Buffalo State, the ease of use of the Tormach puts it above the machining centers the school has.”

As he works to get his Bachelor’s Degree in mechanical engineering, Pyle is using his Tormach machine tools to expand on his educational endeavors, as well as run a small business, known as Arttech Casting Company.