Machinists are always looking for ways to improve their machining - whether that's work on their machine, taking classes, or buying new accessories. Tramming is one of the ways that manual machine (knee mill) owners use to re-establish a perpendicular plane from the spindle to the table, but that term has found it's way into the CNC world as well. The knee mills have a tilting head that moves separate from the base of the machine, by design. As the spindle head of these manual machines are frequently manipulated for various machining operations, there needs to be a way to re-establish, or true up, the mill to a square position. Tramming is the process of getting that tilting head squared up with your table so you're machining is nice and level.

3-axis CNC machines, like Tormach mills, have a cast iron column that can't really be adjusted. That's why for regular maintenance, and peace of mind for many machinists, a CNC machine should be leveled, not trammed. If you do have to make subtle adjustments to the column or head cast joint sections (which is exceptionally rare if leveling is done correctly), then the process is called 'squaring the mill.'

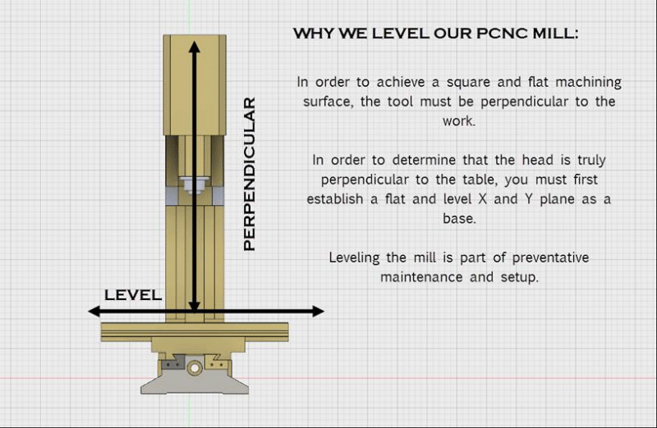

Why Level Your Mill?

In order to achieve a square and flat machining surface, your cutting tool must be perpendicular to the workpiece. If your machine isn't level, your tools won't be perpendicular. This is overtly apparent if you're doing facing with a fly cutter or some other facing operation. The leveling process is important for maintenance, but it is an essential part of machine tool installation as well. This process will not only make your machining better, it will also help your machine last. Leveling may be a tedious process, but it is a fairly simple procedure. Taking the time to sweep your table with an indicator and occasionally level your machine can really improve your surface finishes and all-around cutting.