The world of machining hasn’t made major leaps and bounds in advancements for some time. Controllers are getting progressively better and/or more intuitive, tools are being developed with better coatings and precise geometries, and machines have been getting faster and more robust, but there haven’t been any major advancements in quite a while. Milling machines are pretty well suited to their work, lending to only incremental advances. So, if major advancement has slowed to a crawl, what will the next ten years bring? Some would argue that machines are only going to get bigger, faster, and more precise as the need for manufacturing delves further into the realm of consumer electronics and widgets. This would also lead to more specialized machine operators and a higher cost of entry for upstarted companies. Here at Tormach, we think the key to the future of machining will be based on increasing the approachability of manufacturing. Websites like Kickstarter and IndieGoGo are more than just pipedream enhancers for idea-filled entrepreneurs – they’ve become engines for democratizing what products get made and who will make them.

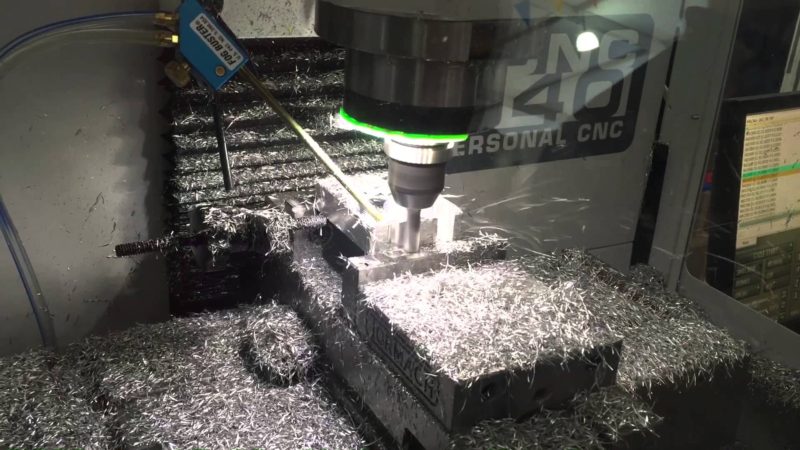

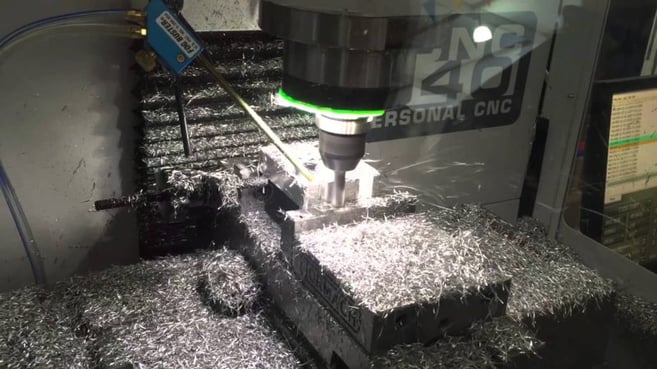

The era of consumer 3D printers is here, and it can be argued that the era of full-on at-home manufacturing is next. Machines like Tormach’s PCNC [Personal CNC] mills are making real manufacturing capabilities available to just about anybody. With the accessibility of inexpensive CAD/CAM software, like Fusion 360 and SprutCAM, machining is more available than ever. That was part of the inspiration for the PCNC 440 – real metalworking capabilities that your kid could operate while fitting in your garage and not breaking the bank. Where will machining be in ten years? It’s hard to say for sure, but manufacturing is sure to only become more accessible, now that so many people have realized the power of making things.