Tormach is a company that makes a bunch of machine tools for cutting many different materials, including metal… and we love cutting metal.

But there’s more to making parts than just making chips. Sometimes those parts need to be presentable, or even beautiful. There is an extensive list of different techniques and treatments that you can give your parts to make them shine (or matte), but here is a shortlist of ways to finish your aluminum parts.

Engine Turning

Also sometimes known as jeweling or perlage, this process can be done with your mill using a metal brush tool. Engine turning can also be done using cratex rods, lapping compounds, Scotchbrite, or abrasive paper, and it can be done manually, though it requires far more patience and leads to some inconsistencies. The process is slow, but it creates that shiny NASCAR-garage feel.

Polishing

Polishing is typically done with a buffer wheel and a polishing compound to make parts really shine. Patience and some elbow-grease is vital to a good polish. This process is one of the most common methods to improving the appearance of your parts.

There’s also a process known as electropolishing, which uses a combination of electric current and an acid bath to polish aluminum.

Anodizing

This is a process, like electropolishing, that uses electric current and acid to create an oxide layer on the surface. This process also makes the surface more durable and corrosion-resistant. Anodizing also allows you the capability to add dyes to your metal, giving it a sheen with some color.

You should always polish a part before anodizing it, as it doesn’t hide a bad finish.

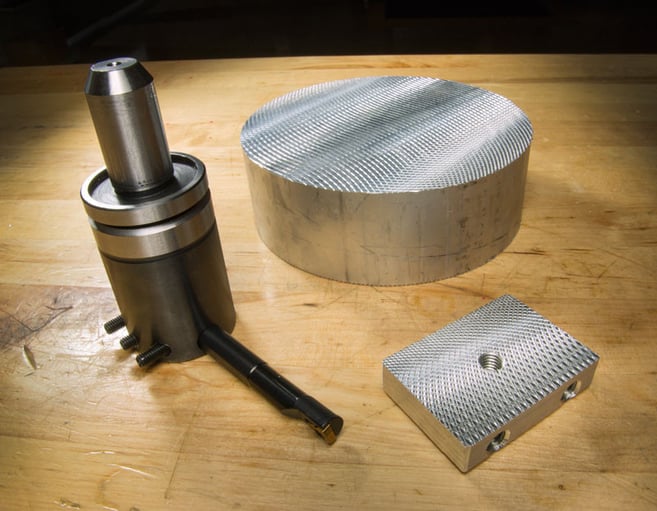

Face Knurling

This is a cutting process that creates a textured pattern on your part – often seen on knobs and knife handles. The process involves cutting a subtle array of patterned lines on a part, providing a gripped surface.

Plating

The process of plating can really change the appearance of your part’s finish. Depending on the type/color of finish you’re looking for, plating can be done with an electric current or it can be done with just chemicals (eletroless).

Plating can create an array of colors, including everything from nickel and bronze to chrome and black chrome.

Similar to anodizing, you should always polish a part before plating it, as the process doesn’t cover up imperfections.

Powder Coating

Powder coating is a fairly simple, inexpensive finishing process that can help protect a part from rust as well as add some color. The paint is applied to your part as a powder, after which the part is “baked,” providing the final finish.

Since it’s a coating, this process can also help cover up minor imperfections or scratches in the surface finish of the metal.