Two years ago, we covered how Frankie Flood uses his PCNC 1100 to make various industrial arts projects and even hot-rod pizza cutters for celebrity chefs. Flood is a professor at the University of Wisconsin – Milwaukee, where he runs the university’s Digital Craft Research Lab (DCRL). “I also teach courses in a newly formed program at the university, called Digital Fabrication and Design,” Flood explains. Because the Digital Fabrication program is an applied program in design, it’s offered to Art students as a BA in Art, but also to Engineering students as a certificate program.

“The program allows students to make functional objects and prototypes. They solve problems that are defined by the student, a professor, or potentially a partnership with local companies,” Flood continues. “My program gives students the opportunity to learn about how to take an idea from sketch to reality by utilizing industrial processes, traditional craft skills, and cutting-edge technology. Art & Design students as well as Engineering students are interested in my courses as they allow for applied learning with hands on experiences.”

In the spring of 2015, Flood co-taught a course called Product Realization within the university’s School of Engineering. The class places mechanical and electrical engineers together with art students to solve problems that local companies are trying to solve. The course allows the students the opportunity to work in a group environment where each person brings their area of specialty to solve a specific problem.

Flood explains, “Companies such as GE Health, Rexnord, Lorence Manufacturing Corporation, as well as local start-up companies buy into the class and assist in mentoring the student groups as they develop a product from initial concept to finished functional prototype.”

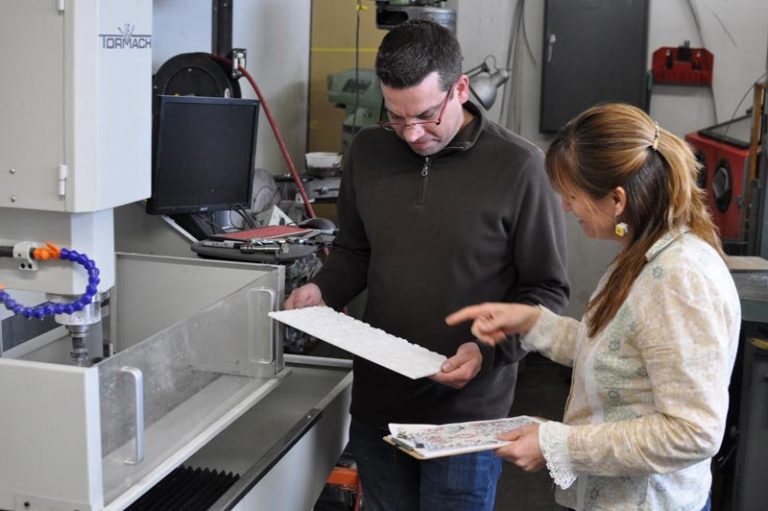

He utilizes the a PCNC 1100 in the classroom as a machine to both teach CAD/CAM workflow as well as give students access to really making things.

“First and foremost, the Tormach mill is approachable. This is something that is important to me as I am teaching students in a class where this is their first encounter with CNC machining,” Flood explains. “Many of the students are aware of the theory of CNC machining, but being able to have confidence to approach a machine and put that theory into practice is important. If their first encounter with CNC were to involve a large industrial scale machining center, that learning curve would be steeper. That said, the Tormach is capable of machining industrial-scale parts, holding tolerances, and providing the students with a real-world applied experience.”

With the emergence of the STEM (and STEAM) initiatives, as well as the maker movement, Flood has witnessed a valuable resource in bringing people from various backgrounds together.

“It has allowed information to be shared freely, and it has knocked down the barriers between professions. We live in a time like no other, where information is easily accessible and the ability to connect with people across the globe has never been so easy,” he says. “Collaboration with large groups of people providing input is possible in ways we could never have imagined.

New software and technology is coming out of these collaborations, and the way in which we solve problems and the tools at our disposable are even more accessible and diverse.” He continues, “Companies are realizing that innovation comes out of an applied approach to learning through making, and working with materials. I started manual machining by reading a copy of South Bend’s ‘How to Run a Lathe’ because it was difficult at that time to get information on using a lathe. That’s when industrial arts programs were being shut down, and the trades seemed to be dying. It seems that, now with the emergence of the ‘maker’ movement, that an awareness of the importance of making in a creative environment, is on the rise.”

Flood has seen, first-hand, the value of making in education, with both his students and his own learning experiences. “With the extensive number of Tormach users sharing knowledge via the internet, I am able to demonstrate to students how, just by having this single machine, a business can be built around it and the associated knowledge of owning and running a Tormach. This gives my students the ability to dream of ideas and engage in entrepreneurial activities that are centered on problem solving and innovation.”