New manual updates available We've updated our manuals, so update your bookmarks - we've just added manual revisions for both PCNC 1100 and PCNC 770. PCNC Series II Manual PCNC 770 Manual Major changes are:

- Updated Exploded View and Parts List (Chapter 10)

- Additional comments on Cutter Compensation (Chapter 6.8)

- Edits to Gib Adjustment Procedure (Chapter 9.5.5)

- Edits Troubleshooting Section (Chapter 10)

- Other Minor corrections and edits

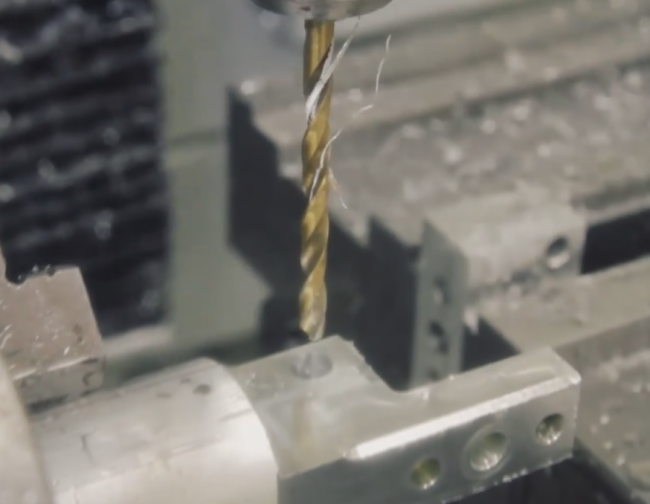

Probably the two areas for interest for most will be expanded commentary on Cutter Compensation, and greater detail in Gib adjustment procedure. Both sections have changes resulting from some technical efforts we've taken on in the last year to (1) provide better clarity om how to properly adjust gibs, and (2) understand the with better certainty how cutter compensation should be implemented, and why it doesn't always work. 4th Axis Part for CNC Fundamentals As some of you may remember, I mentioned that we were retiring our Stirling engine project from the CNC Fundamentals class, at least for the time being. What's the replacement project? A very cool - and useful - dial indicator holder. Here's one of the parts we'll be making: 4th Axis, with multiple work offsets and also a slitting saw and a dovetail cutter. Pretty cool!