Kevin Corley is a construction project manager that started his CNC journey with a non-descript CNC router. He quickly found it a struggle to make parts out of metal and began to explore what Tormach had to offer instead. While working on prototypes for a client’s Kickstarter campaign, he picked up a Tormach 770M CNC mill, and didn’t look back.

When he got a new puppy and needed a dog tag, he realized an opportunity and started prototyping his own. “I felt like I could merge my design experience, and working with metals, with some of the soft grid elements of dog products, and it’s been really interesting going down that pathway.”

Tormach’s 770M mill fit the bill for his side-hustle businesses as he did some work through Xometry, occasional parts for clients, and prototyping and production of his canine merchandise. He picked the 770M because of its footprint and power requirements, having limited space and a home shop.

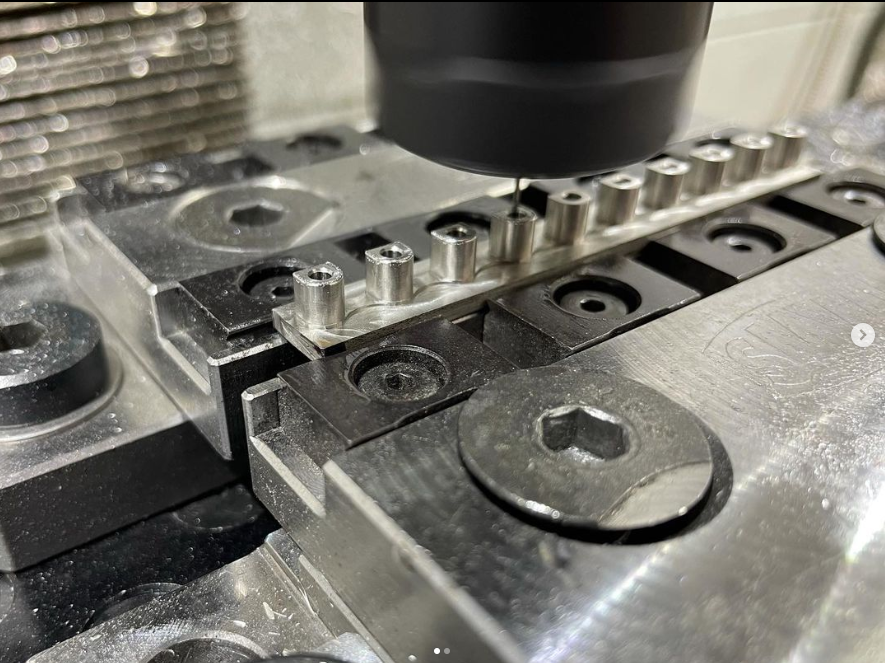

The Tormach 770M CNC mill is built to machine all types of materials from aluminum, wood, plastics and even titanium. Not only can it get the job done (and the next one and the next one), the 770M is a little workhorse, even in tight spaces. It runs on single-phase power, and its modular design lets small business owners like Corley buy now and start making parts, and when ready to add on, can improve performance as needed.

Corley started his business in Connecticut, but he currently resides in Colorado. And yes, he took the 770M cross-country! “I packed up everything, palletized it like when it was first shipped to me, and put it in a POD.”

His business, Wild Paws Pet Company, offers high-quality, American-made dog tags, but he’s also started to expand his forward-thinking product offerings with a unique leash design.

The majority of what Corley cuts is aluminum, but he really enjoys using brass and copper in his products as well. “Definitely way more expensive materials, but they add nice accents to products. With the 770, I have the flexibility of trying to find something that's cost effective or maybe use some of the more expensive materials that I want.”

While he’s still doing some shop work and production for his existing products, Corley is also prototyping new products. Currently, he’s working on a dog collar with similar design elements to his leashes and tags. “It's great to have this machine and be able to think of products and prototype something - do small runs - quickly and easily.”

With his background in mechanical engineering and leveraging ProvenCut to calculate feeds and speeds, Corley feels he has yet to use the machine to its fullest capacity. “I'm just one person and I'm doing design, CAM programming, and I gotta run the machine. That's probably the biggest challenge, just balancing everything.”

Corley's story is one of passion, perseverance, and craftsmanship. His love for creating things with his hands led him down a path that eventually led to the development of his own business. With the help of his Tormach 770M CNC mill, the business and product line are expanding.

Check out Wild Paws Pet Company and follow Corley’s journey on Instagram.