Last week, we talked about the importance of precision and the tools that are essential to help every machinist take measurements. Another vital set of measurements that every machinist needs to utilize are tool and work offsets – essentially, knowing where your work piece is and how your cutting tool will come into contact.

MEASURING AND LOCATING WORK OFFSETS

Work piece precision is arguably the most important use of measuring tools. The TTS Touch Tool (PN 31283) does exactly what its name implies – it mounts using the Tormach Tooling System and touches off on the work piece. With 0.001” resolution, this simple tool allows you to take an accurate measurement of the height (Z) of your work piece.

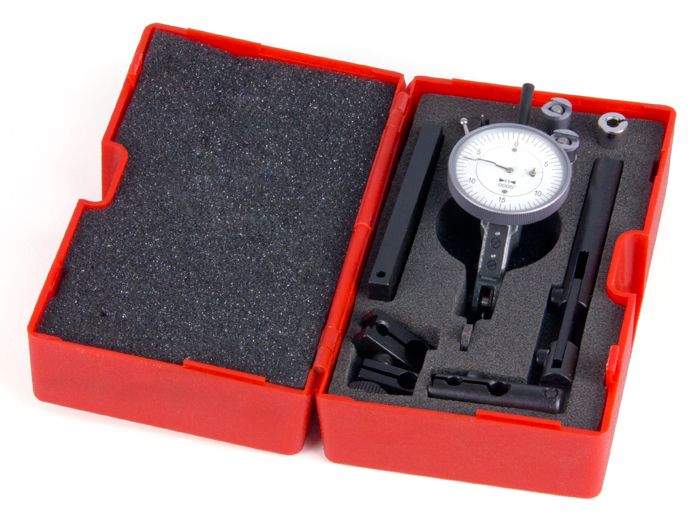

Knowing where you work is and keeping things square is vital to the CNC machining process. The Interapid Style Dial Indicator (PN 31948) allows you to take accurate measurements and even measure the precision of a hole. With a 210° swivel arc, this indicator can give you precision anywhere you need it. Even with some of the more complex measuring tools available, this indicator is essential for every machinist’s work bench. The Haimer 3D Sensor (PN 33029) is incredibly accurate (+/- 0.01 mm) to make sure that locating edges and surfaces in X, Y, and Z is done with rigor. If work pieces are measured inaccurately, the whole part could be ruined before the first cut is made. Similar to the Haimer, the Digitizing Probe (PN 31858) measures your work piece with precision, but the difference comes with ease of use. Using sealed electric contacts and red LED touch indicators, the Digitizing Probe talks with our PathPilot software and provides a quicker way to set up work pieces. Finding edges is important – it’s been vital to machining since the days of manual mills, long before CNC emerged. That’s why many machinists rely on an Edge Finder (PN 32660), sometimes known as an edge wobbler, to orient the X and Y of work setups. Our ½” edge finder has a 0.200” tip diameter with 0.0002” accuracy. [youtube]BoIB_Fatt44[/youtube]

MEASURING TOOL HEIGHT OFFSETS

Having an accurately measured work piece is important, but it is just as important to know your tool heights and have that information plugged into your control software. The Digital Height Gauge (PN 31761) operates like a calipers for your cutting tools. When combined with a Granite Surface Plate (PN 31713) you can quickly calculate the height of your tools in 0.001” graduations.

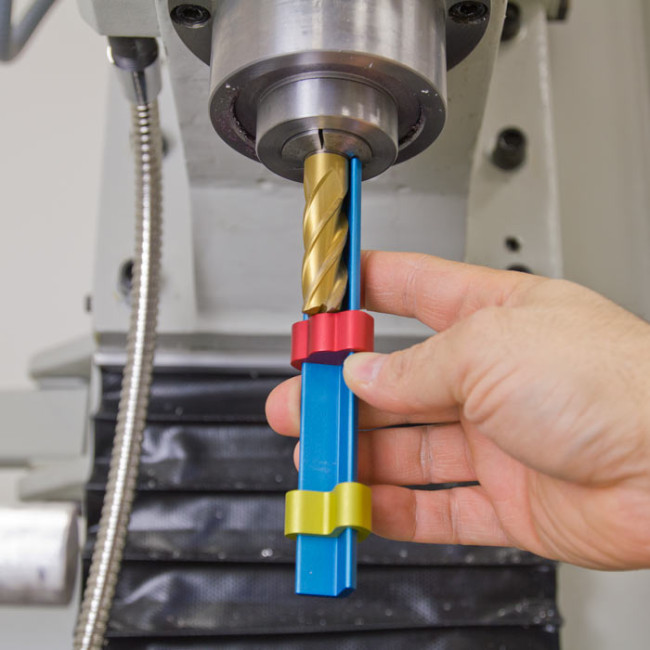

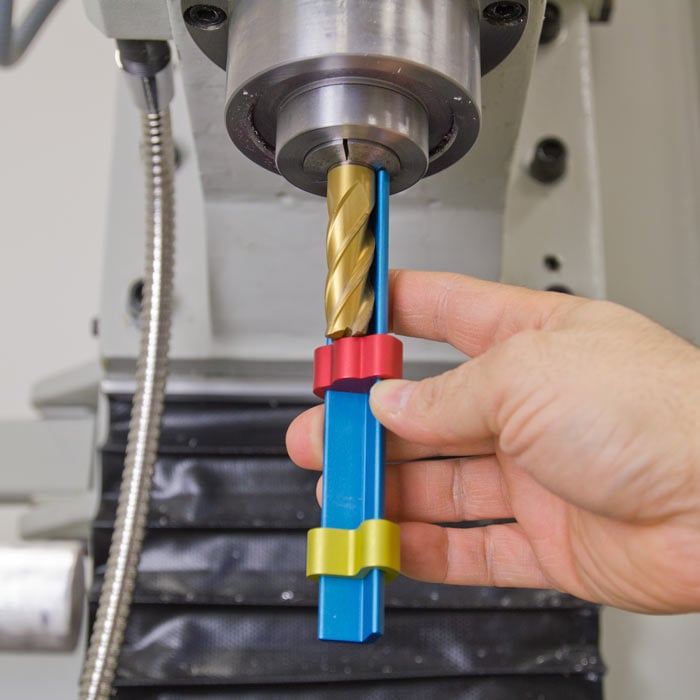

The Stop-Loc (PN 32894) can be used for both tool and work offsets. This tool can measure drill length and tool stickout within +/- 0.005”. It can also be used to measure work piece stickout on a lathe, collet chuck, or a vise (up to 3" diameter, up to 5 1/2" length). Using the two moveable stops, this tool can give you measurements for precision. The coup de grace of measuring tool offsets is the Tool Setter (PN 31875). This device plugs directly into the controller and allows you to quickly touch off tools in the spindle to measure their length. Once the tool hits the carbide sensor pad, the tool setter imports the data into PathPilot, providing fast and accurate tool offsets. Are there other tools you’d like to see Tormach carry that could help you measure your work and equipment more quickly or efficiently? Comment below and let us know.