Years ago, when I was starting out as a DIY machinist, my limiting factor was always the ease and convenience of rough cutting stock.

It isn’t that I started with the world’s greatest mill and lathe from the get-go, because I didn’t. They were typical crotchety, rickety, hobby machines and I don’t miss them too much, but I got a lot of projects done with them without too much complaining. It took me a long time to realize it, but where I was fussing and cussing the most back then was cutting rough stock to size before I could even get it to those machines.

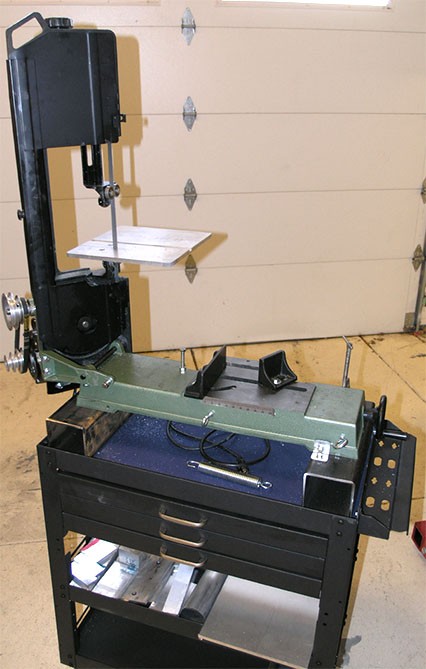

I was a pack rat for raw metal back in the day. Plates, structural steel, and long rounds were piled all over my garage shop. Almost all of it was too large for my machines, so before I could do much of anything, it had to be cut down to size. I started out life with the ubiquitous little Harbor Fright Band Saw.

I paid all of $41 on eBay for the thing (it had some cosmetic issues), bought a decent blade for it that cost more than the saw, and proceeded to hate on the little stinker through many projects.

What you see is what it looked liked towards the end of its useful life. I’d mounted it on a cart (for more storage and portability), added a nice table for upright work (normally it saws in horizontal mode), added a little oil dropper to lubricate the cut, and generally learned how to tune it up to work with minimal hassle. After all that, and especially after I learned to tune it up, it was decent, but very slow and still somewhat finicky. What do you want for $41?!??

Somehow, I came across what would’ve been a far better initial purchase–a DeWalt Multicutter.

Wow, what an improvement! This is a poor man’s cold saw, and just the thing for DIY CNC’ers. It’s basically a carbide toothed saw blade in a miter box format with a motor that spins it slow enough (still much faster than a cold saw) so the blade can live.

I’ve sliced through everything from cast iron to make a table for a disc sander to endless aluminum stock to steel tubing. It’s so much faster and easier that, despite having a full-sized industrial band saw now, I still go to the Multicutter for any kind of smallish diameter long stock and save the band saw for plate work and curves.

I’ve used a lot of abrasive cut-off saws, and I like this thing so much better. The price is actually pretty reasonable–you can buy one on Amazon right now for $435, direct from DeWalt with free shipping. It just beats the heck out of fighting with a cheap band saw.

A pro-shop is going to have much better solutions, but even pros might find one or two of these to be handy in a corner for quick and easy work while the bigger machines are busy.

The blades actually last a lot longer than I expected. Mine could use a new one, but still cuts. I plan to drop it by the local saw blade sharpener and see if that’s a cost effective way to renew it. If not, new blades are not that much either.

For a DIY situation, I’m not sure there’s much better. Of course you can order your stock cut to size, but that prevents you from keeping much on hand. You could buy a bigger, nicer band saw – I took that route when I found a gorgeous, fully restored, industrial band saw, which I've dubbed the Old Beast.

I love the Old Beast, and it is just the thing for sawing plate like the photo above. I stuck a VFD on it to deal with it’s desire for three-phase power (not available at home for me) and use it a lot. But, for stuff that fits on the DeWalt, I keep going back to that. It’s faster and more convenient than the Old Beast.

For really big plates, I fire up my plasma cutter from time to time. I can’t wait for someone to come out with a reasonably priced small-scale waterjet machine – that would be the ultimate.

In the meantime, look into that DeWalt and keep eyes peeled longer-term for a really nice band saw. You won’t be sorry!

This post originally appeared on the CNC Cookbook blog.