Some people think of face mills as large diameter tools with lots of inserts. These kinds of face mills need big spindles to push them efficiently, but a fly cutter provides an effective way to face on low horsepower spindles and can deliver superior surface finishes - here's why:

Fly cutters have previously been known as tools for manual machinists, but as Bob Warfield at CNC Cookbook explains, “Many CNC machinists realize that a very fine surface finish may be better done by fly cutting.”

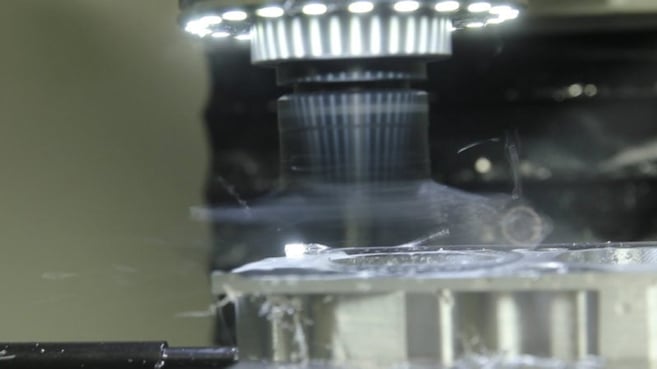

While face milling provides a quality surface finish at higher speeds, a fly cutter can create a much finer finish because you are only cutting with one insert. Face mills use multiple inserts, which allow for more removal of material, but unless you’re spending a significant chunk of change, the height of the inserts can’t be individually adjusted, causing varying chipload among the different inserts. A fly cutter provides a single cutting surface, which isn’t as fast but is much more uniform and develops into a smoother surface.

Cost can also be a factor. We’ve seen Tormach customers use large face mills on their machines, but those tools are expensive – and so are the inserts at $10-$20 each. If you have upwards of $600, or much more, to spend and customers waiting on parts, a face mill might be the route to go.

But if you’re looking to get fantastic surface finishes and speed per operation isn’t as much a factor, you can pick up the TTS Superfly cutter stocked with inserts for both softer materials (like aluminum) and harder materials (like steel) for less than $150. As with most things in machining, there are many different ways to do face milling and create impressive surface finishes, but it’s all about calculating how much time and money you’re willing to invest in your part.