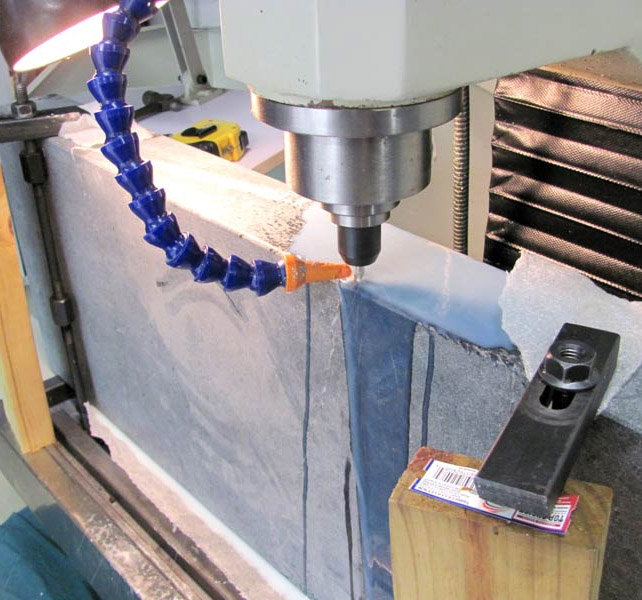

Late last month, I posted about the soapstone carving that Jeff Rasnake does with his Tormach PCNC 1100. Mostly, I wanted to show off some of his creative fixturing methods for big heavy things (like the picture above). It turned out that lots of blog readers were interested in the actually details of soapstone machining - feeds, speeds, tool selection, etc. I reached out to Jeff again and he was kind enough respond.

From Jeff:

Here are a few details on how I am successful machining soapstone:

I use carbide tooling, endmills or engraving cutters, depends on the job. I normally run around 2000 rpms and 3.0 - 5.0 inches per minute (IPM) I use the slower speeds and feeds on the more delicate pieces where there is a chance of a piece breaking off. I have cut as much as .500 deep per pass at 3.0 IPM. The soapstone turns to a muddy mess when wet. I use a layer of shop towels or rags to filter and contain the wet powdery excess. I always use flood coolant. I have a tile saw for roughing out the work piece and flood that also with water.

There is a softer grade of soapstone and a harder grade. The soft grade is more or less free cutting and can be cut more aggressively. The harder grade deserves less feed and speed, similar to cutting stainless.

I don't know of any dangers of working with the soapstone except for cutting dry and breathing all the dust. I avoid the dust by wet cutting everything. The dried excess is like talcum powder. This link here talks about usage of soapstone powder: http://www.ashirwadminerals.com/soapstone-powder.html

I have been running the heck out of my Tormach for the last four years and cutting soapstone for about 2-1/2 years. The soapstone work has gotten really popular for me.

I hope this answers some of the questions.

Thanks.........

Jeff Rasnake

Thank you, Jeff!