Why are some end mills so much more expensive than others, and are they worth the cost? Every machinist must have wondered about this question at some point. Many develop fierce loyalties to the brand that has worked for them. Manufacturer’s recommended speeds and feeds fall into bands depending on the material and type of cut, but they are not all the same. Different endmills really do perform differently, and they sure do come in a wide range of prices. In this article, we’ll take a look at the three main factors that cause end mills to perform differently: the grade or quality of the carbide they’re made from, their geometry, and their coatings.

Carbide Grades and Quality

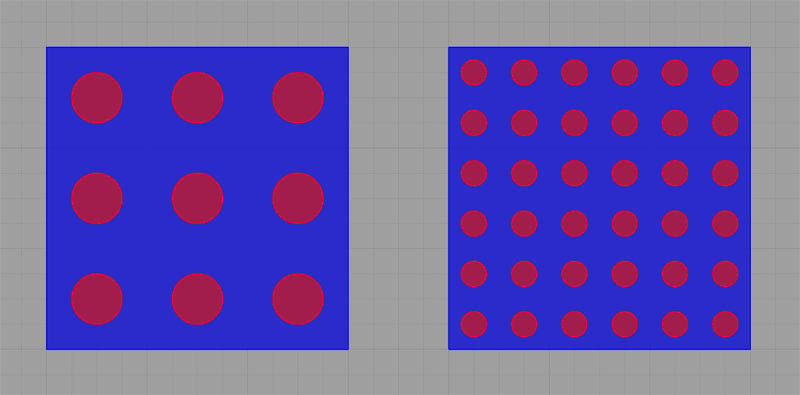

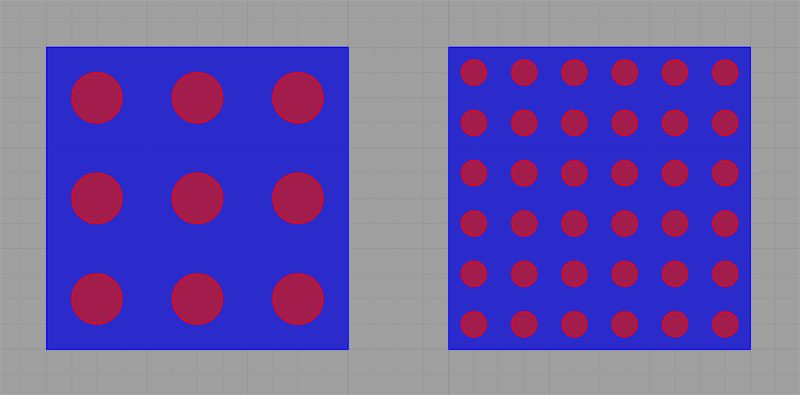

Let’s start with the material carbide end mills are made from. While end mill manufacturers frequently refer to their cutters as “solid carbide”, in truth, they are more accurately called “cemented carbide”. BTW, I don’t think they’re trying to pull the wool over anyone’s eyes, marketing just can’t resist more adjectives and you could as easily say they use “solid” to refer to endmills that don’t use inserts. Nevertheless, the material is not a solid metal at all, but a matrix composed of tungsten carbide (which itself is tungsten and carbon in equal parts) held together with a binder–typically cobalt. As one would expect, it is the tungsten carbide and not the binder that does the serious cutting. Hence, a lot of the quality of the carbide is a function of how much tungsten carbide grains there are versus how much binder. Cheap carbide has a lot more binder than expensive high-quality carbide. This can come about either by way of how the material is prepared or because of the grain size. Manufacturers use terms like “sub micron” and “micrograin” to describe the better grades. As the grains of tungsten carbide get smaller, there are more of them relative to the binder. Imagine a container of ball bearings. Suppose we fill one container with large balls and another same-sized container with much smaller balls. Then we proceed to fill each container with water until it is full to the top. Which container can hold more water? The container with the larger balls has more space between the balls for the water and hence holds more water. Think of the ball bearings as the tungsten carbide grains and the water as the binder. Here is an illustration of this large grain/small grain packing phenomenon:  As it turns out, the smaller grained cemented carbide formulations are more expensive to prepare, especially if the highest quality standards are maintained. Yet, by doing so, we get much better performance from our cutters. They stay sharp longer because they expose more of the extremely hard and heat resistant tungsten carbide and less of the relatively delicate filler.

As it turns out, the smaller grained cemented carbide formulations are more expensive to prepare, especially if the highest quality standards are maintained. Yet, by doing so, we get much better performance from our cutters. They stay sharp longer because they expose more of the extremely hard and heat resistant tungsten carbide and less of the relatively delicate filler.

Geometry

Geometry is a huge determinant of end mill performance, and there is a lot to cover. Exotic geometries serve many functions and we can’t possibly describe all the many variations out there in one article, but let’s go through a few of the more common examples. Let’s start with the basic helix itself. We have a high helix, a low helix, roughing/finishing helixes, and variable helixes. What does it all mean and what does it do for the machinist? The “high” and “low” terms refer to the helix angle of the endmill. Imagine the angle between the edge of the helix (the spiral flute) and the flat bottom of a standard endmill. A low helix endmill has an angle of 35 degrees or less whereas a high helix endmill has more than 35 degrees. A good roughing + finishing in one cutter compromise is a 38-degree helix angle. The highest helix angle possible would be a straight flute cutter like some CNC router bits. If you’re familiar with their disadvantages, you may be wondering what the pros and cons of high versus low helix cutters are: High Helix Advantages:

- Cutting forces are directed more vertically and less horizontally, which reduces tool deflection.

- Chips are evacuated more quickly.

- Axial rake is more positive, which makes for better shearing and lower cutting forces. This typically means they can be fed faster. The lower cutting forces mean lower horsepower requirements.

- The core of the tool is thicker due to the shape of the helix, so therefore the tool is stronger.

High Helix endmills are typically used in tougher harder materials because they wear better, although they can also be used in aluminum. The biggest disadvantages of High Helix endmills are that they tend to chatter more, and they really bite into the material. With soft materials, they’re much more likely to pull out of the holder. Surface finish may also suffer relative to a low helix design. Read: Why Coatings Aren't a Conspiracy Low Helix Advantages:

- Less likely to chatter

- Typically perform better in soft materials

Their disadvantage is that for their target tough materials, they have lower feedrates and hence lower material removal rates. Variable Helix end mills are considered state of the art these days. The idea is to vary the helix along its length in a couple of ways. The flutes may not be evenly spaced and the helix angle may vary along the length. The goal of the variable helix is to fight chatter. Since chatter is a resonance effect, anything we can do to break up the resonance of the flutes beating against the workpiece will reduce chatter. Varying the flute spacing means they don’t hit on a regular beat, for example. Now to make it even trickier, most designs will orchestrate the variable spacing of the flutes with the helix angle so that the combination of the two means the flutes are equally spaced but that spacing is different at every point along the length of the tool to reduce the chatter. Needless to say, there are many variations among manufacturers, many patents, and a whole lot of potent voodoo magic! Another variety of exotic geometry involves various tweaks that affect the rake of the edge. As mentioned, more positive rake like we find in a high helix has a lot of benefits. For starters, manufacturers employ variable rake along the edges as yet another way to fight chatter. Too much rake leads to a weak tool. But wait, there is a technique called a “ski-flute” that puts a little dish right under the edge to provide maximum rake at the edge while keeping more core strength characteristic of lower rake designs. Some manufacturer’s put chip-breaker type features inside the flute to help performance too. Check out Mitsubishi’s MSTAR high helix end mills for one example. How about a chamfer or corner radius? Typically these features prolong tool life and may also enhance surface finish. We’ve barely scratched the surface on end mill geometries. By now you must be getting the idea that it gets very complex. With that complexity comes increased manufacturing costs. Adding all these clever features means each endmill requires a full-fledged CNC tool grinder. And, the more complex the features, the longer and more difficult will be the grind. Micro-polishing the edges is yet another treatment that could be regarded as geometry and that certainly adds more grinding time. Sharpening a modern endmill is no longer possible with a manual tool grinding machine. If you try it, you’ll just destroy the exotic geometry the cutter was meant to have.

Coatings

Some coatings are nothing short of magic when it comes to their performance impact. G-Wizard calculator’s default surface speed is 20% higher for a TiAlN coated end mill versus an uncoated carbide end mill, and that’s on the conservative side. These days, TiAlN is very mainstream, and there are much more exotic coatings out there such as the Hydrogen Free Diamond-Like Carbon coating featured in the image to the right. Coatings are often proprietary in nature, and even the same chemical composition may not guarantee the same results. I don’t want to get into a big discussion of coatings here. Since they are proprietary, the finer points are often not well documented anyway. Suffice it to say coating is another way to add performance and cost to a cutter.

Conclusion

Take the most expensive grade of carbide, the most exotic geometries that require complex CNC grinding to produce. Add a killer coating applied with the latest state-of-the-art techniques and machinery. Voila! You’ve just produced a recipe for a modern super cutter. By now, you should be able to see both why it is a better endmill from a performance standpoint and also why it costs more to make them. Those bargain basement imported end mill sets don’t have any of these things going for them. But do you really need a super end mill in your shop? The answer to that question is heavily dependent on the particular economics of your shop and project. Some machinists are reporting cases where an endmill that costs 3x as much lasts 5x as long. Clearly, they’re coming out ahead by purchasing a more expensive endmill. Your mileage may vary. Our point here is not to sell you on expensive endmills, but rather to explain why some are so much more expensive and what benefits some of these improved technologies may bring. This post originally appeared on the CNC Cookbook Blog.