Toolpaths are the heart of computer aided manufacturing (CAM), and by association, incredibly important to CNC machining. But, toolpaths are more than just the pattern tools make to cut your parts.

More Than Just Efficiency and Time

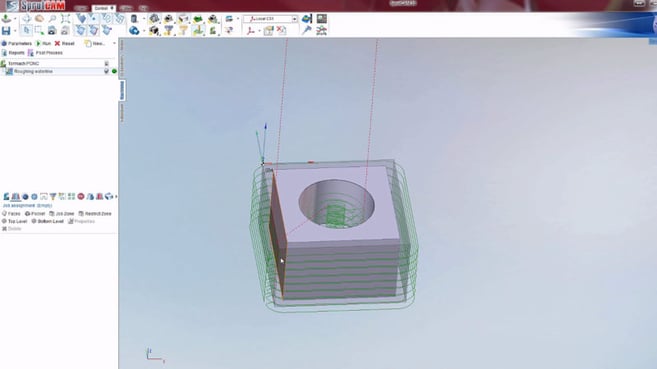

One of the more obvious values in thought-out toolpaths is based heavily in a machine shop environment. In a for-hire shop, time is literally money, and in such an environment, proper toolpaths can cut runtimes down and reduce breakage. In large production environments, cutting a few seconds off the runtime of a part means more parts and can swing profits by hundreds, thousands, or even millions of dollars. Toolpaths can have a much larger role to play outside of a production environment or industrial shop. Jake Steuber, one of Tormach’s SprutCAM experts, explains that if you CAM up a part without tweaking your toolpaths, “You quicken up the CAM side of things, but can add enormous amounts of time on to the machining side of things.” More time at the machine is not only inefficient, but those drawn-out toolpaths can also drastically affect your tool life.

Adaptive Clearing

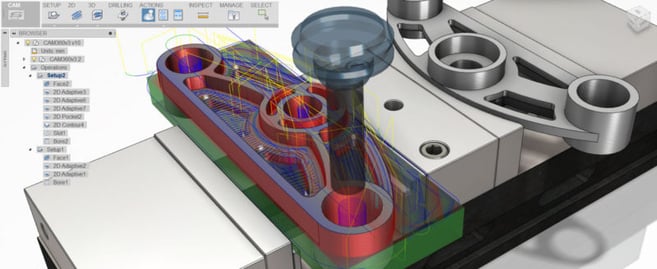

Cutting things faster can also mean better tool wear. SprutCAM and Autodesk’s Fusion 360 have adaptive clearing (or adaptive roughing) capabilities. An article from Mold Making Technology says, “a larger axial depth of cut allows the use of more of the cutter flute length without overusing the bottom of the cutter. Additionally, the generated heat is spread out along the whole cutter flute length, rather than concentrated at the bottom of the tool.” This means more material removal, faster cycle times, and less tool wear. Tormach Brand Ambassador, John Saunders, uses adaptive toolpaths in Fusion 360. He explains that as an example, with carbide tools that have ¾” flutes, “With these toolpaths, you’re using more of the carbide that you’re paying for, and getting more use out of the entire tool.” Another key toolpath feature that Saunders focuses on is rest machining, which means taking duplicate adaptive operations, but the second operation only takes what remains on the part.

Less Tool Wear Means More Reliability

Not that long ago, CAM software capable of programming adaptive toolpath strategies cost upwards of $30k a seat, but with access to software like SprutCAM and Fusion 360, almost anybody with a CNC machine can experience the confidence that adaptive toolpaths provide. Saunder’s says, “Picking the right toolpaths provides more reliability. With adaptive toolpaths, I am more willing to walk away from the machine, which frees up my time to do other things in the shop. That’s the beauty of CNC, and with adaptive toolpaths, that’s less stressful – I’m less likely to break parts, damage work pieces, damage tools… it’s just a confidence thing.” Fusion 360 Manufacturing Product Marketing Manager, Jeff Jaje, says more about the value of proper toolpaths, “If you are careful ahead of time, you have fewer problems downstream. It’s one thing to see a digital tool move across your screen, but another to have a real tool cut through your steel. Choose the wrong strategy or parameters and you may at best decrease tool life, provide poor finish, have greater tool deflections, and at worst scrap your stock.” Access to toolpath technology is incredibly valuable to all types of machinists, from the at-home hobbyist to the production shop, but keeping toolpaths at the front-of-mind while working with CAM is key to better parts and a more satisfying machining experience.