Educational spaces are always looking for better (and less expensive) ways to teach and provide access to real tools. That’s why Tormach has always had a foot in the world of teaching CNC, whether we’re talking about folks using our machines to teach machining, like John Saunders, or STEM educators using the machines in a more traditional classroom environment. Providing approachable, capable machines has been the goal of Tormach from the beginning.

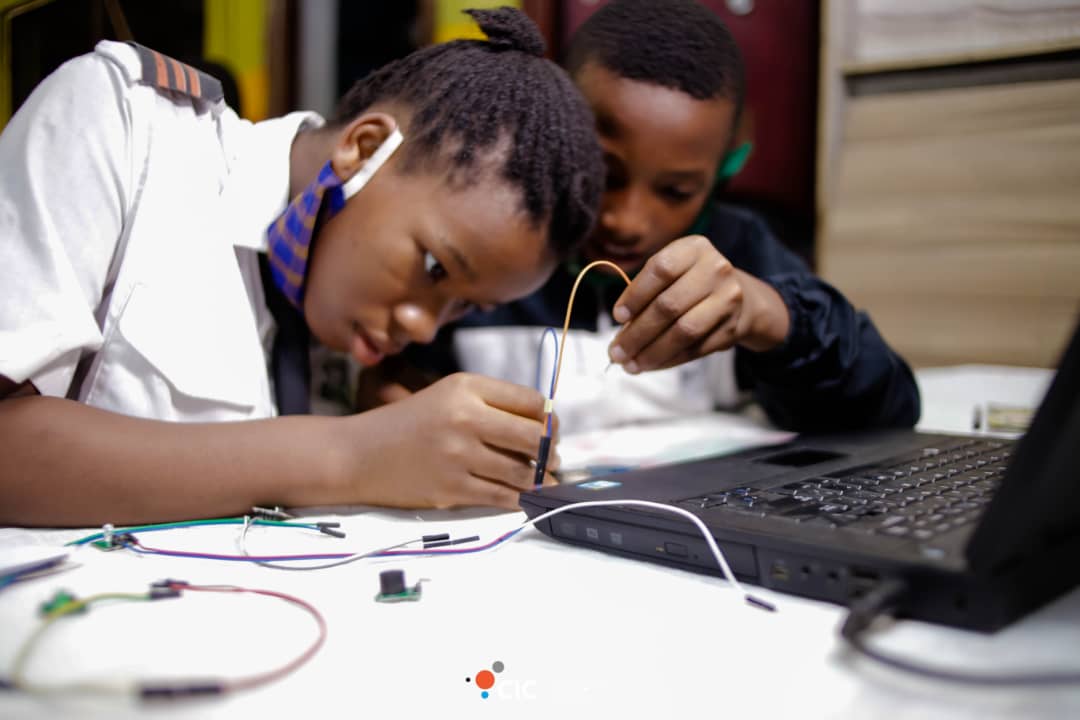

As the company has grown, we’ve seen Tormach machines find their way into classrooms and maker spaces all over the world. Like the 1100M Mill being used by Make Maker in Nigeria.

Building a STEM Program in Nigeria

Onyinyechukwu Goodness Richard (Goodness) is a renewable energy enthusiast and STEM educator who co-founded Make Maker to develop innovative, practical, and relevant tools and products for experiential learning in schools.

Her background with CNC started in 2019 while enrolled in a training program that was focused on CAD, CAM, and digital fabrication, and was organized by Clintonel Innovation Center. That’s also where she was first exposed to a Tormach machine.

“Studies have shown that Nigerian Students are losing interest in Science and STEM-related courses,” Goodness explains. “This is partly due to the theoretical approach of teaching STEM employed in most schools, rather than hands-on learning. This is the reason for founding Make Maker.”

She explains, “Make Maker is focused on developing products that simplify learning science concepts through project-based learning thereby making learning science fun, engaging, and interesting.”

Image courtesy of Make Maker

Goodness uses Make Maker as a medium to tackle the inequalities that young girls experience in STEM-related courses in Nigeria. During their STEM classes, students come up with ideas for projects to develop and Make Maker assists them in bringing those projects to life. They are also trained in digital fabrication skills such as CAD, manufacturing, 3D printing, and of course, CNC milling.

“Since education is a propeller of development in any society, Make Maker’s aim in the educational sector is to provide innovative products and services to educate, inspire, and spark the interest of students towards STEM-related careers,” she explains. “We have conducted and participated in training over 1000 students in STEM, digital fabrication, Computer-Aided Design, Computer-Aided Manufacturing, CNC milling, rapid prototyping, etc. During our training programs and classes, there is a growing number of students who are pursuing STEM-related careers in CNC machining, product design, CAD, and robotics.”

A Tormach Mill for STEM

Make Maker uses an 1100M to teach manufacturing and the basics of CNC work. Goodness explains, “The Tormach machine's simplicity of use has given us the medium to effectively teach students CNC milling. The 1100M is used to create basic CNC projects for students using wood and plastic. The idea of the class is to make students understand the application of the CNC mill.”

Goodness explains that one of the biggest advantages of using a Tormach mill is the simplicity of the operation. She says, “As a woman in tech, I have come in contact with really complex explanations of some scientific concepts, which makes it really hard to digest. The Tormach mill has been the easiest route to learning CNC machining, especially for students.”

Goodness continues, “Tormach has simplified a complex system such as CNC machining to which a 15-year-old can easily understand and operate the machine. Because the 1100M was so simple to use, I had the confidence to incorporate CNC machining into our training curriculum with students. The PathPilot interface is user-friendly and helps us create a step-by-step plan to operate the CNC machine.”

Beyond just projects with students, Goodness and her team have also created molds and other CNC-related projects. “We have done a 4L blow mold, a plastic injection face shield mold, shoe soles molds, name tags, and a number of other things.”

She sees the importance of STEM growing rapidly as we move into the future, which is why she has her sights set on helping the next generation of female STEM professionals. Her hope is that STEM will become more prominent in Nigeria, and will lead to youth being more career-ready by the time they complete formal schooling. And with the help of a Tormach 1100M, they seem to be well on their way to creating the next generation of engineers, manufacturers, and entrepreneurs.