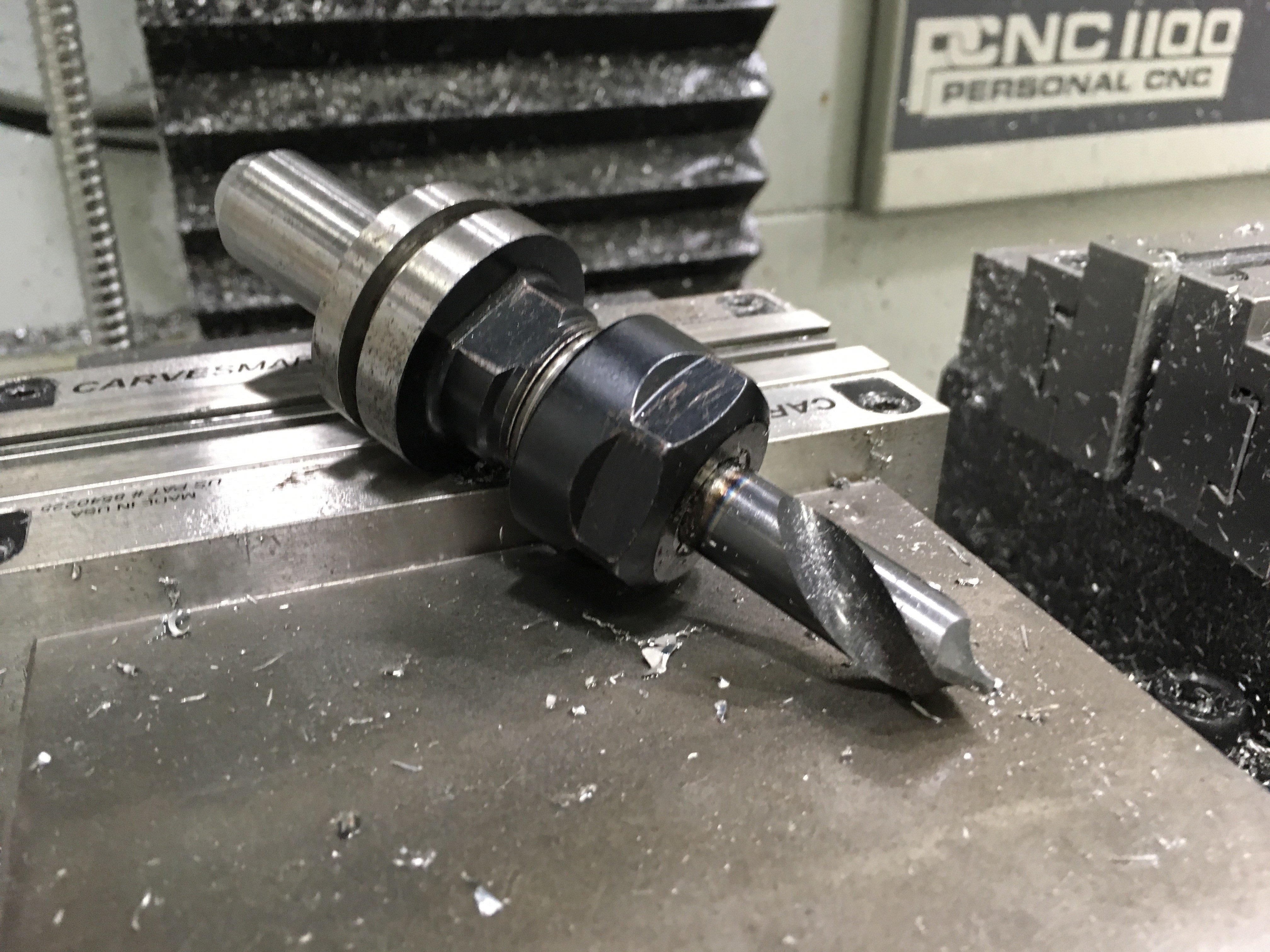

Machinists are familiar with spot drills–they’re stub length and have few or no flutes. These little drills are designed to be extremely rigid so that they can precisely spot a hole for a twist drill. Maximum meat in the shank keeps them on target. The goal is use the spot drill to make a little dimple in the work-piece that keeps the twist drill from walking so the hole winds up in the right place.