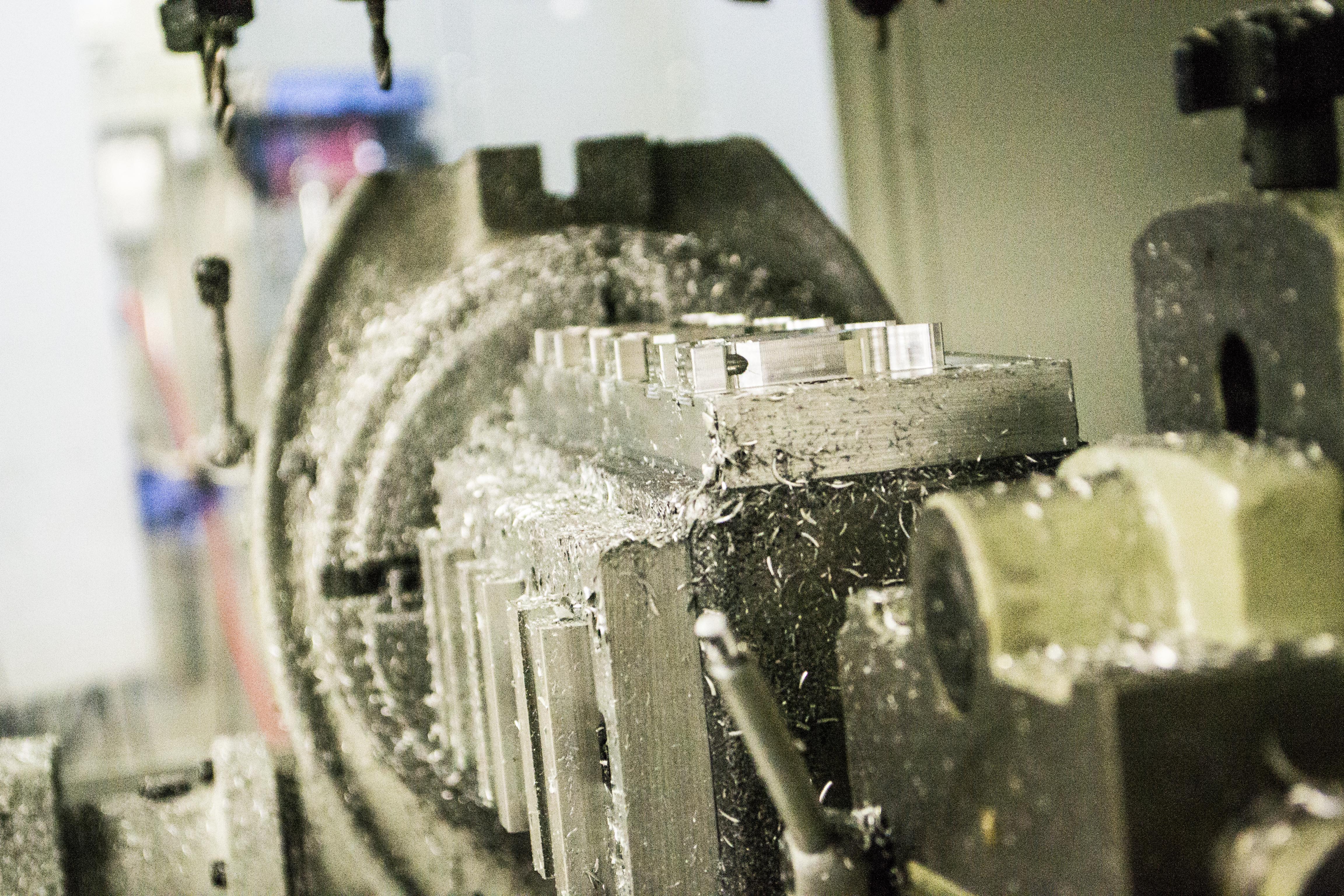

Sometimes, there can be a lot to CNC machining – everything from computer programming to materials science is involved – but paying attention to a few things can make a big difference in the parts that you make. Here are six little things that can make a big difference with your CNC machining.