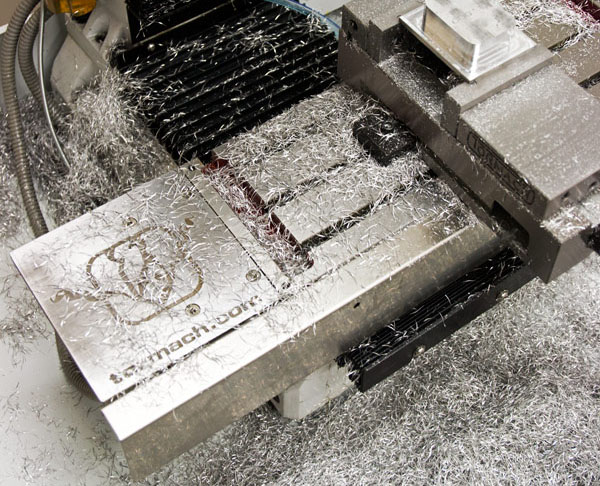

When you’re making parts, there are a lot of things to keep in mind… tolerances, feeds and speeds, tool wear, workholding… the list goes on and on. Whether you’re making your own parts or stuff for a customer or even shipping components off for Xometry, the final finish of your product is important to remember.