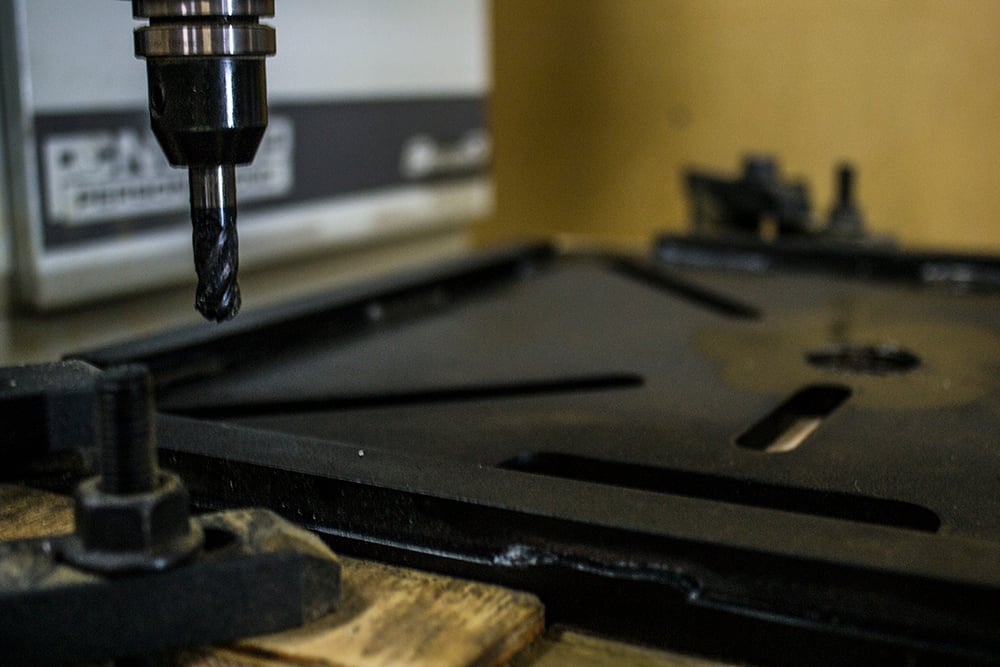

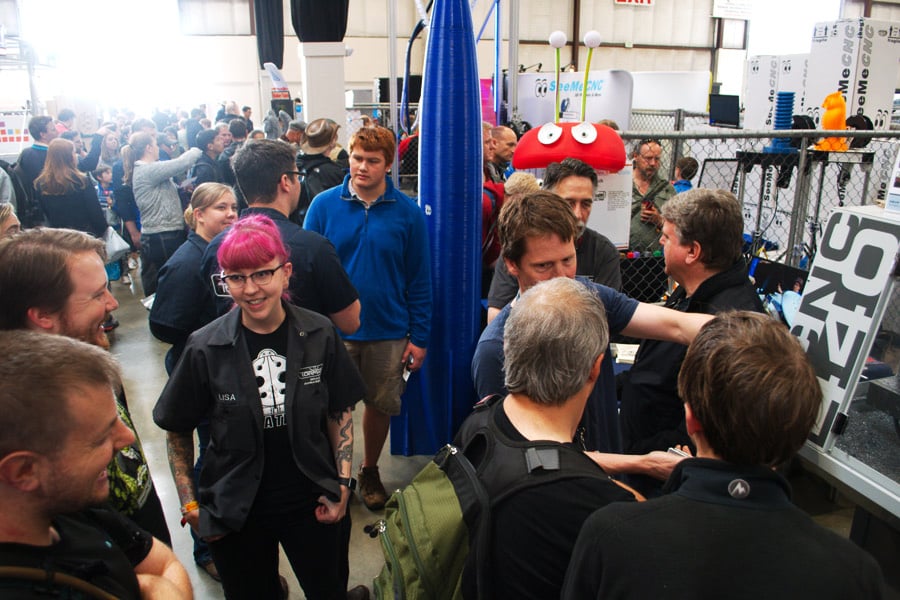

The world of CNC starts with software. Specifically, CNC starts with CAD software to design and develop your part before you ever create toolpaths and make chips. SOLIDWORKS is one of the largest CAD companies out there, and every year they host SOLIDWORKS World, until now.