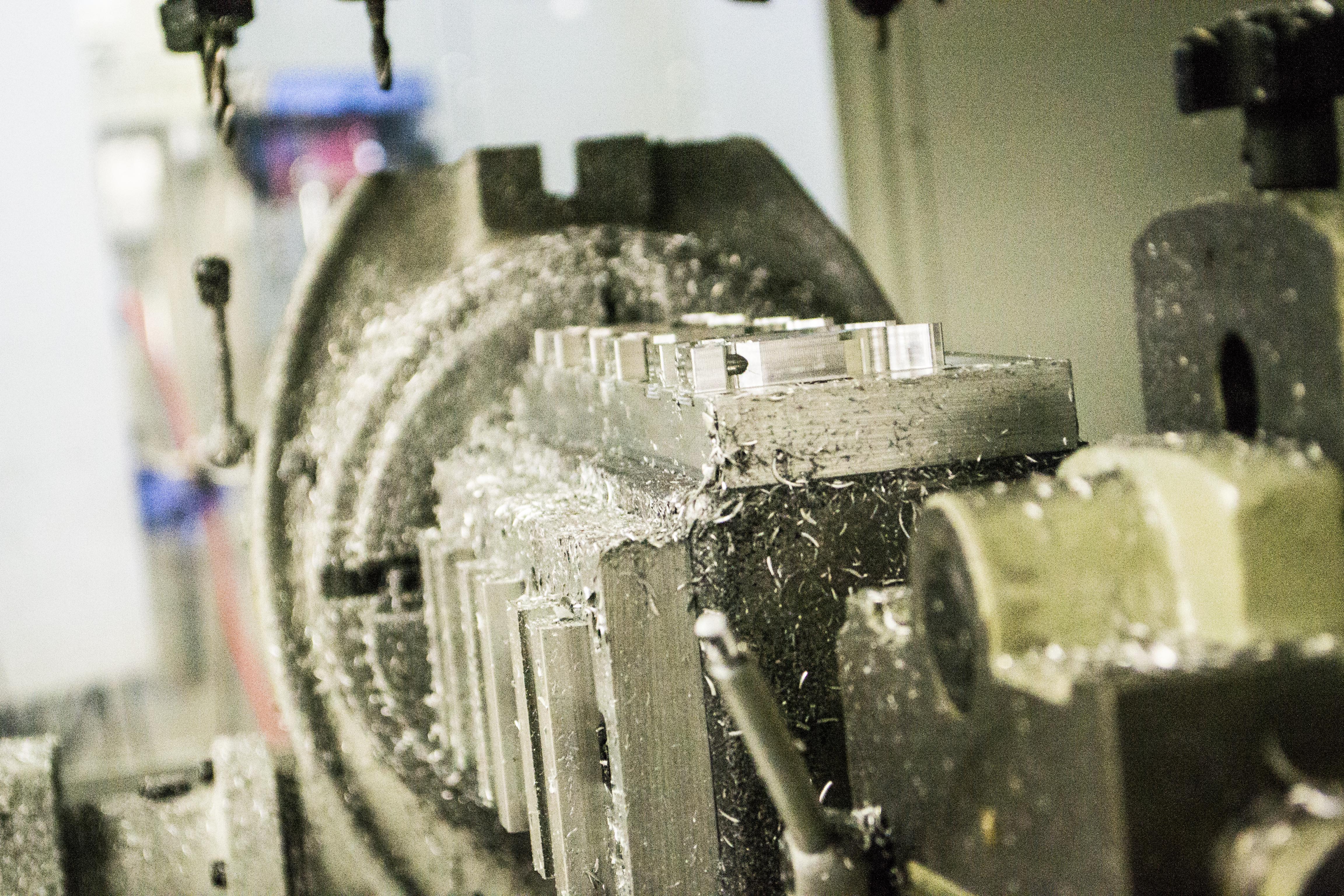

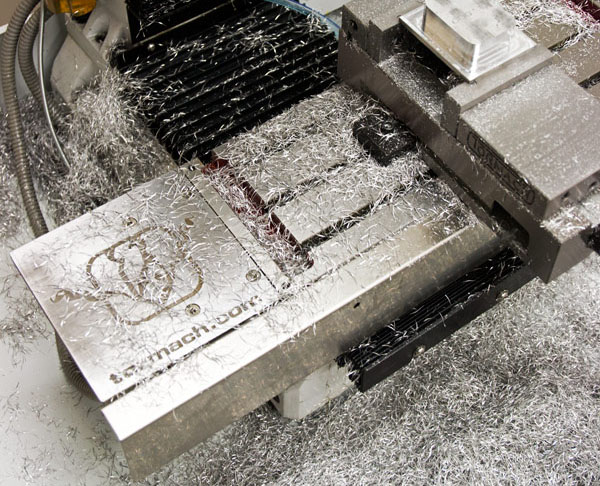

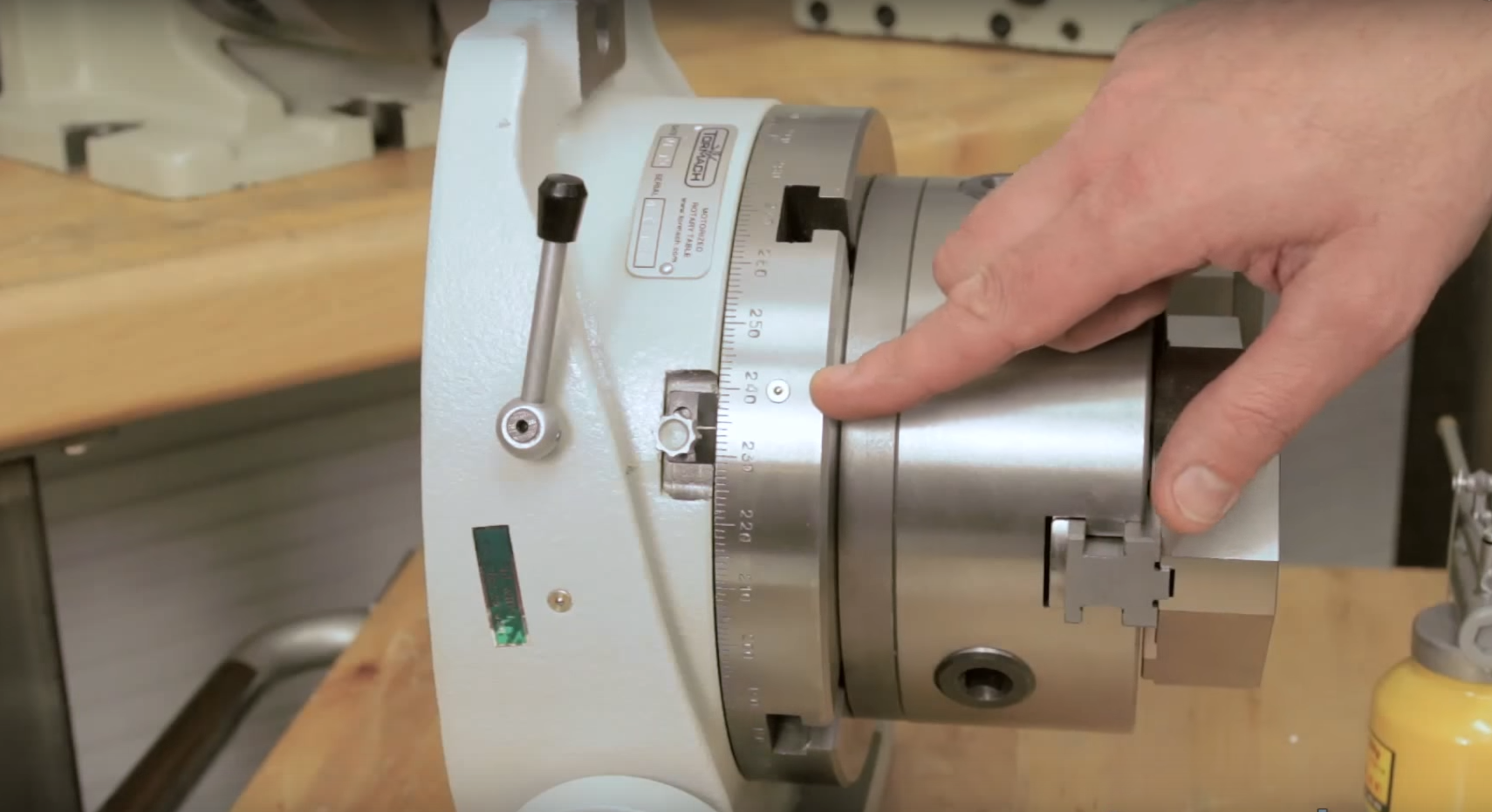

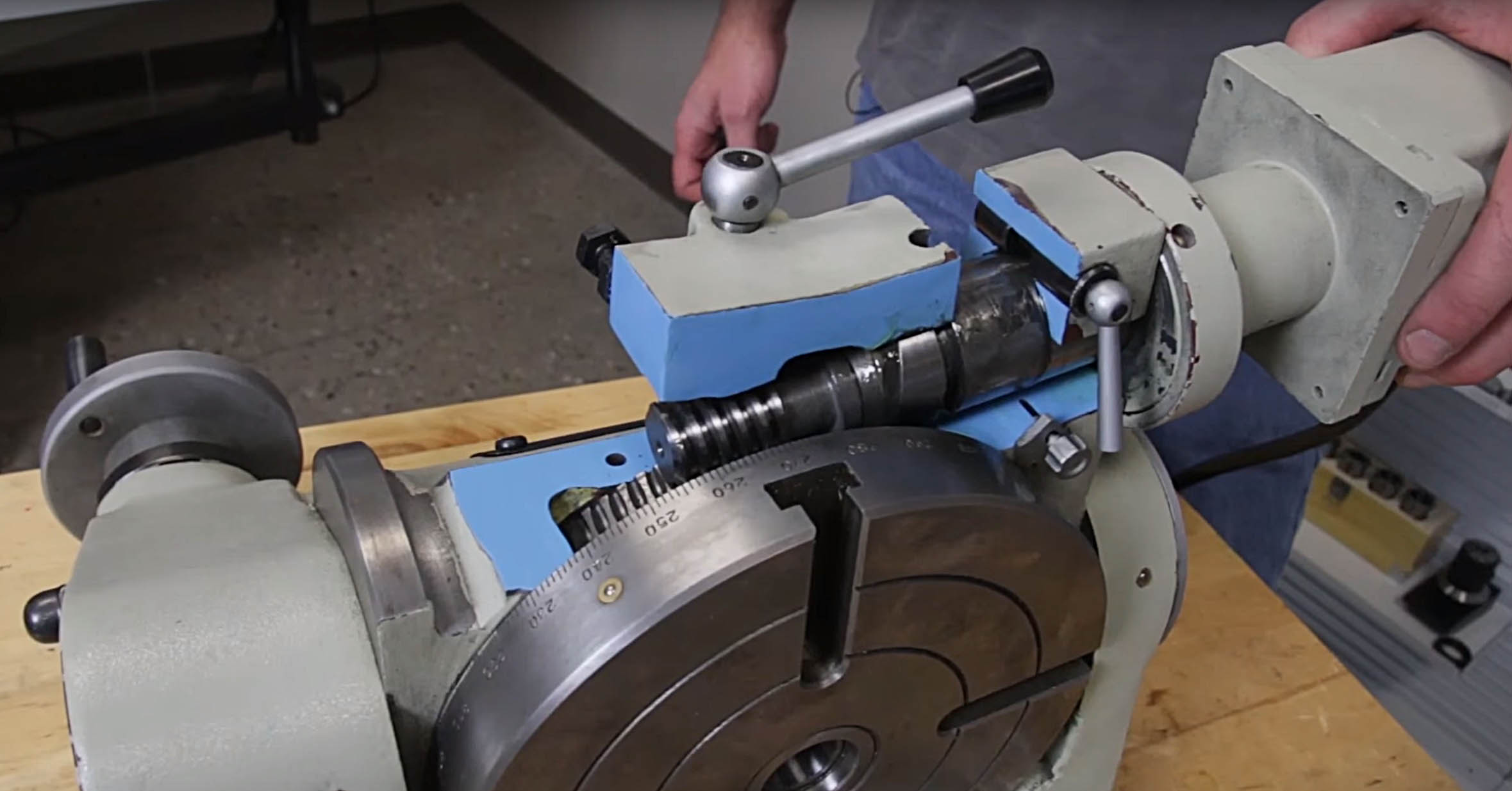

Machine maintenance can make all the difference in the world inside your shop. Whether you’re talking about HVAC, hand tools, or machine tools, keeping your shop clean and maintained will not only make things last longer, but it will also help you become/stay efficient.