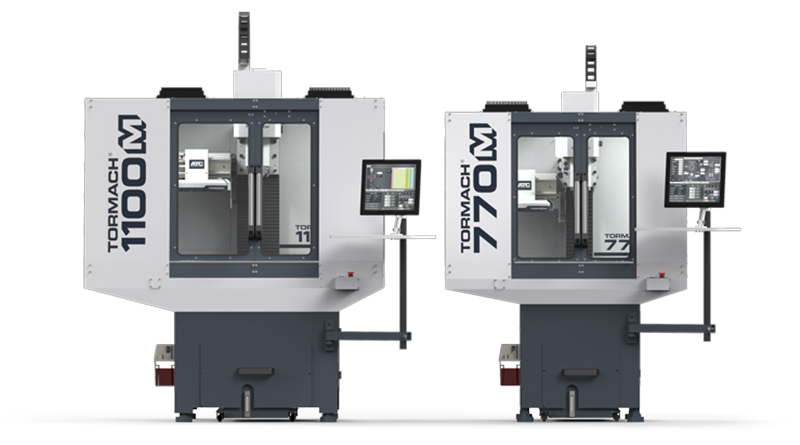

About two months ago, we spent some time at the filming of BattleBots, and our experienced team helped builders get their robots fixed after some brutal fights. While we were there, a few folks noticed that the 1100 on site looked different than a Series 3 PCNC 1100.