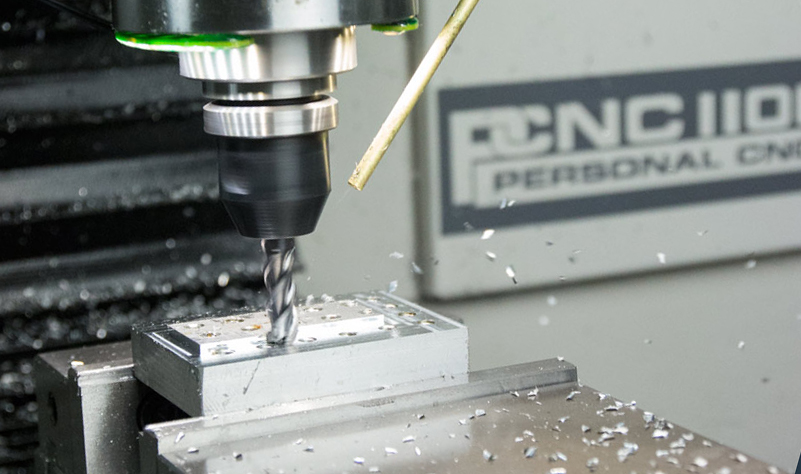

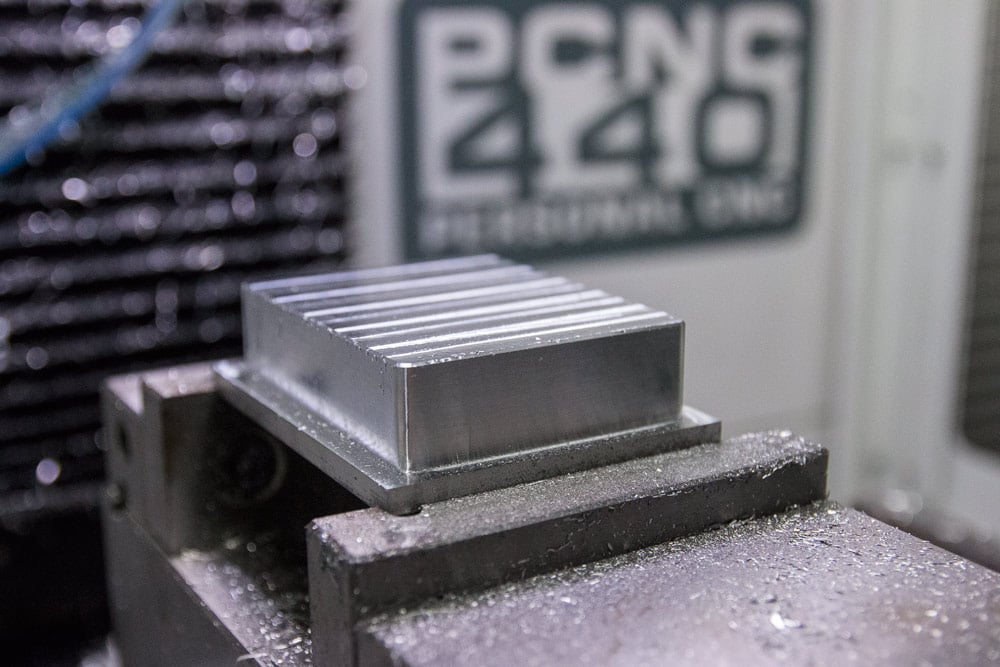

Most of the time, machinist’s focus on the hardware aspects when they think about surface finish: – Do I have the right feeds and speeds? – Is my setup and machine rigid enough? – Is there too much runout on the spindle? This is definitely the right place to start, but it’s not the end of the story. A great many factors affecting surface finish are tied up in the CAD/CAM software used to create the part program. For example, the part in the photo on the right exhibits a faceted surface finish. This is definitely a software issue (although there are certain servo mis-tuning situations that can lead to that sort of thing). Let’s take a look at some of these critical software issues that affect surface finish: