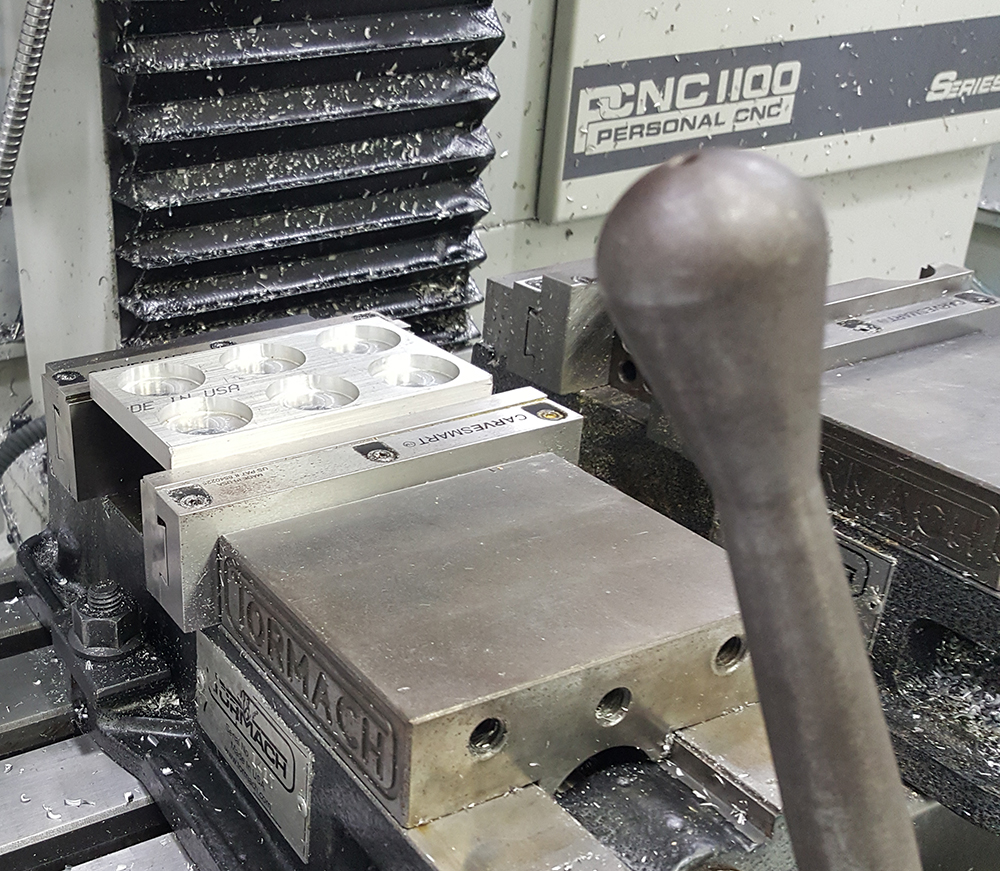

Experiential education started to emerge in the 1980s, but it seems like technical education teachers knew this long before all the research was published. Keeping content fresh and finding projects students are interested in is a hurdle that seems to get consistently harder to overcome. Tormach just released its project library to help you do just that.