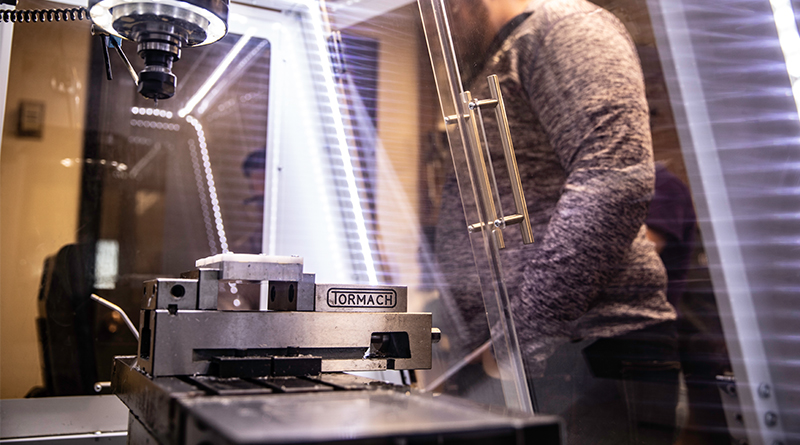

Adding hands-on experiences in the classroom makes CNC machining easier to both learn and understand - especially in the commercial world of manufacturing and engineering. Matias Perret is an instructor in the College of Engineering at the University of Iowa, and he has used both a PCNC 770 and a PCNC 440 to give his students CNC manufacturing experience.

“Part of what we try to do down here is give students some hands-on CNC experience on the different machines that we have and with different manufacturing methods,” he explains.

“And then teach them how to utilize these methods to design components for that specific CNC manufacturing process. Design for manufacturability is key to connecting the digital world of CAD to real-life parts and products.

Students could very easily 3D-print their designs and then assemble them, but that won’t undergo the rigors of testing if they want to validate what they’re manufacturing. That’s the value of having something that can actually cut metal in the shop.”

Eric Mensen is a student at the University, “A lot of the students probably have never even heard of what G-code is, neither have the hands-on CNC experience. They have no idea what G54 and G90 are. So, the university teaches them that if we have a part in the 3D model world, that part has to come out of a physical part in the real world, like a piece of raw stock.”

The University of Iowa program focuses on helping students understand the manufacturing process as they design their parts using CNC machine technology

“There’s a lot of students that, by the time they’re through the program, they can run with it,” Mensen explains. “They can have their own part modelled, set their own sequences up, and they can come over to the Tormach CNC machine and make their parts.

Design engineers, as a whole, understand that you can design just about anything you want with 3D modelling. But, that doesn’t mean you can actually make it in the real world.”

Mensen continues, "This the gap that the PCNC 440 in the University of Iowa lab is starting to close. If the design engineer can design a product from the get-go that has CNC manufacturing in mind, then that means that the people running the CNC machines are going to have a much easier time making the part. At the end of the day, if it’s easier to manufacture, that’s going to reduce the costs.”

Giving students access to an approachable, yet capable CNC machine tool has helped the program realize its full potential.

“As far as the PCNC 440 is concerned, it’s good because the prototypes that our students are developing are going to be a step above,” Perret explains. “Now with this machine in the lab, we give students some basic instruction on it and then it’s off to the races. They get to manufacture whatever they think up.”

Perret emphasizes the ability to give students real CNC machine manufacturing experience is the best way to teach.

"Witnessing first-hand what happens when a design fails or fails to be manufactured correctly is valuable to teaching students proper design techniques. You can’t beat the hands-on CNC machine experience to learn about these processes.

Bottom line is that it’s fun! Students enjoy being able to make stuff and it helps them learn the material and it gives us the opportunity to emphasize the theory behind the design of CNC machine manufacturing.”