Obviously, Thanksgiving is the time of year to reflect on what we are thankful for. Even in a year as crazy as 2020, we can still find a lot to be thankful for, but let’s step outside the average list.

While we’re all thankful for our families and our health and the excellent food we will scarf down over the next few days, machinists and CNC users tend to have their own lists of things they are thankful for… perhaps, even things they couldn’t live without!

Haimer 3D Sensor

Once this little piece of equipment entered our lives at Tormach, we didn’t want to ever be without it. While there are less expensive ways to indicate and locate edges, the Haimer 3D Sensor is simple, fast, and works in three axes.

Haimer Tips

While the Haimer 3D Sensor is a fantastic tool, it can be delicate. All it takes is a quick flip of the jog wheel in the wrong direction or accidentally switching from 0.001” steps to 0.1” steps to watch a Haimer tip shatter!

This is one of the perks of using a Haimer 3D Sensor… the tip breaks away without destroying the more expensive tool. There are always a pile of Haimer tips floating around the Tormach shop, because even the most attentive machinist will break one or two.

Machinery’s Handbook

Dubbed the bible of the metalworking industries, the Machinery’s Handbook has everything from basic math calculations to metrology reference to tap drill charts. While having a reference book sitting in your shop might seem archaic to some, this tome is worth every inch of space it takes up.

Aluminum

Aluminum is a great material for a number of reasons, but when it comes to machining, we should be thankful that it exists.

Obviously, depending on your part, you need to use specific materials, but aluminum is a fantastic go-to… mostly because it is so easy (and forgiving) to work with. It isn’t magnetic, it’s easy to get ahold of, and it’s far softer than steel.

Whether you’re prototyping for a part that will be eventually cut in a harder material or your final part is made out of aluminum, it can’t be denied that this light-weight metal is something to be thankful for - even if it’s just about making chips.

RapidTurn

This one might sound self-serving, since the RapidTurn is a Tormach product, but hear me out on why we should be thankful for this little tool.

More often than not, shops aren’t very big. That’s why Tormach mills fit so well into so many workspaces. But, what if you want a lathe too?

No machine shop is complete without having some sort of turning capabilities. And while we’d love to sell a 15L Slant-PRO lathe to everybody that needs to turn, sometimes they just don’t fit. Even smaller lathes might have a hard time fitting in a small shop space.

Since the RapidTurn fits right on the bed of your mill, you don’t need to take up any extra space to add turning to your shop.

Sweet, Sweet Carbide

If you’ve ever used subpar tooling, you know what I’m talking about here. While carbide tools are often a little pricier than their high-speed steel brethren, they provide an edge that is going to stay sharper for longer. These sharper edges provides a cleaner, neater finish on your parts, and the edge won’t get dull for quite some time.

Carbide is often seen has a staple if you want to get quality surface finish, but what’s more, you can recycle broken tools… for cash! You can trade in busted carbide and put it toward your next tool(s).

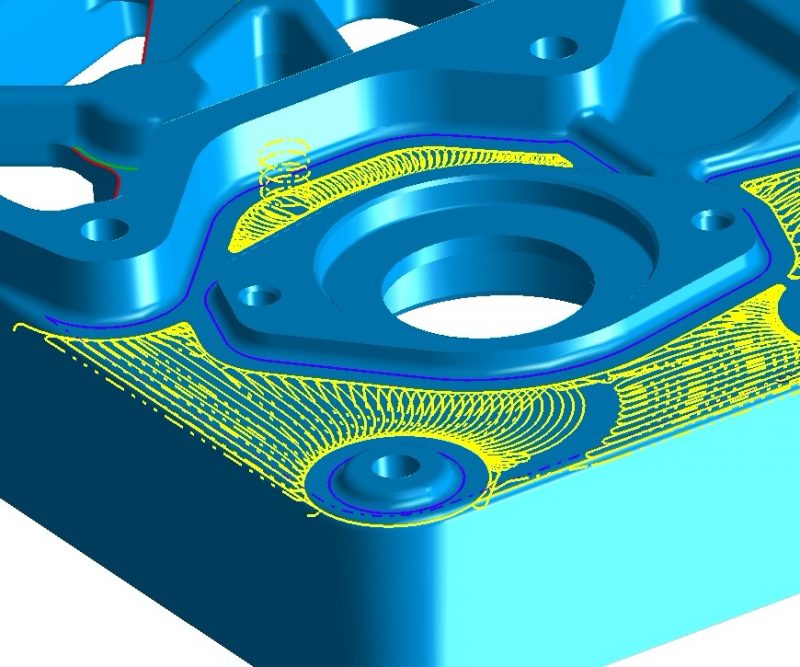

Adaptive Roughing

Adaptive roughing provides faster stock removal and helps maintain a constant load on your tools. This means that parts get made faster and your tools will last longer.

Basically, adaptive roughing is an intelligent toolpath that keeps the load on your tools constant. That means faster material removal and more precise cuts. If you haven’t used adaptive roughing before, you should… it’s awesome!

Magnetic Grabbers

Losing things in your shop is common. What’s worse, is losing things behind tool chests, machines, or other hard-to-reach places. Every shop should have a couple of these magnetic grabbers!

It’s a simple design - a magnet on the end of a stick - but we couldn’t be more thankful for these. Whether you dropped a bolt into a machine crevice or just need to hold a metal object in place, a magnetic grabber is worth every penny!

microARC 4th Axis

This little unit is a fantastic little addition to any Tormach mill. Adding a microARC 4 4th axis gives you the ability to do a whole array of different cuts and create unique geometries that would be difficult or impossible otherwise. Beyond just what a 4th axis adds to your machine, the microARC has a harmonic drive, which adds precision and rigidity to the gearbox, and makes this accessory really diverse.

Tormach Customers & Community

While we are certainly thankful for all of these tools in the machine shop, one thing that continues to keep us thankful year round is Tormach’s loyal Customers and our shared Community.

The community of Tormach users, former owners, and future customers is amazing! One place where this community congregates is on Facebook. If you haven’t joined the Tormach Operators Group or the Tormach M & MX Owners Group yet, you should. Lots of knowledge and great stories are shared all the time.

Have a safe and happy Thanksgiving!