Last September, we talked about a few tools that you never knew you needed in your shop, but when it comes to machining, there are a million different ways to do everything. So, here’s a sequel to help you discover some tools you never knew you needed in your shop… or maybe you did know, and you can just use this as a justification for all those tools.

Drill Press

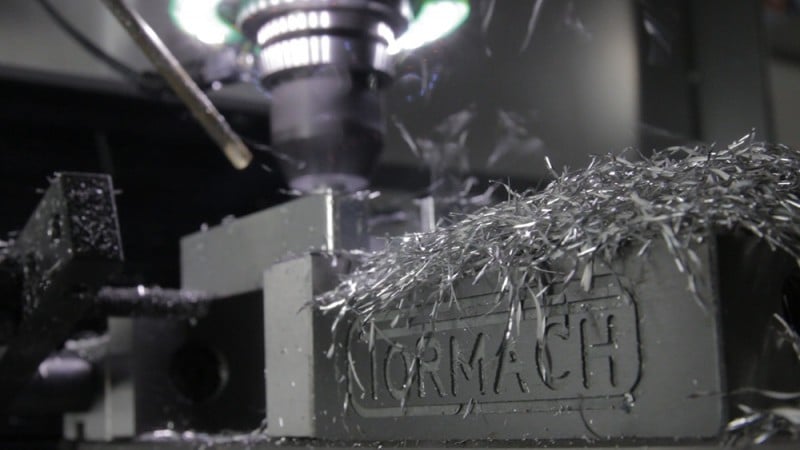

You might think, “Why do I need a drill press when I have a sweet Tormach mill?” While that is accurate, do you really want to bog down a mill for just one hole? Drill presses provide the ability to create holes (just like your mill), but without spending the time to set up a mill or the need to do any programming. While this tool may be overkill to some, if you have a busy Tormach mill, a drill press can be quite an inexpensive, time-saving accessory.

Angle Grinder

If you’ve worked with metal before, this one is a given. Angle grinders are great for deburring, polishing, surface cleaning, or even cutting, when you’re in a pinch. A good angle grinder can be very robust and can chew up your parts rather quickly, but these things are more in the ‘brute force’ category instead of the ‘finesse.’ Many shops (garage or professional alike) do more than just cut metal – welding has a big spot in many of our hearts as well. Welds don’t always have the most finished appearance and they are usually in hard-to-reach spaces. An angle grinder can help with that, too.

Scribes

A machinist’s scribe allows you to mark a piece of metal with a fine line. Pencils and markers are great for making rough marks on stock, but if you want precision, a scribe with the way to go. Scribes are more often associated with manual machine shops, but they still have a place with CNC.

Vises

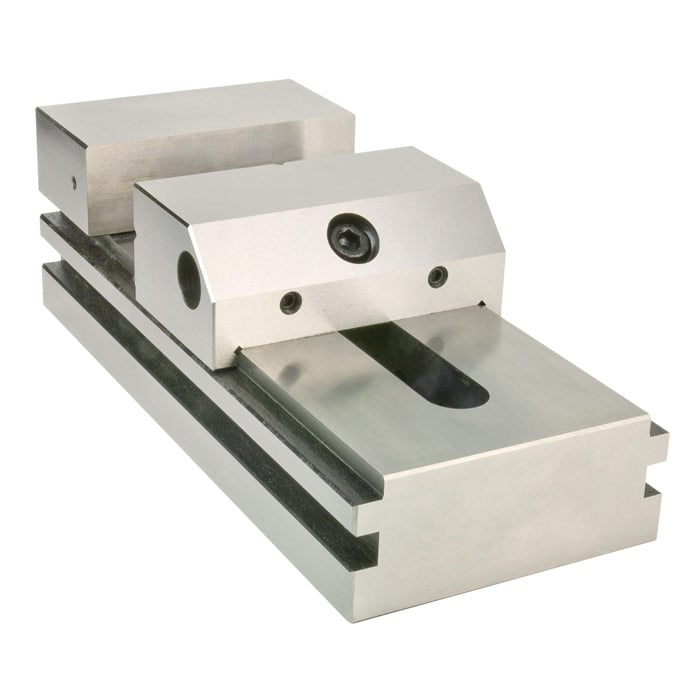

Of course vises are important to have for workholding on your machine, but having a few different vises besides those used for machining is important. It might seem like common sense, but even the simplest tasks can be improved in quality if you hold things with a vise.

You can get especially intricate and precise if you use a toolmaker vise.

Nuts n’ Bolts

Fasteners are vital to have around the shop. You might have threads you need to test, odd workholding that suddenly needs a screw, or just basic repair of a component where the bolt fell behind your bench. Having a rack full of various nuts and bolts is a must-have in any shop.

Arbor Press

If you need to push things like bearings, shafts, and arbors into place, an arbor press will get the job done. While a rubber hammer can achieve the same thing (sometimes), an arbor press allows more precision and control while doing so. This can save you time and damage to your part – not to mention frustration. You can also utilize an arbor press to do tasks that require a similar motion, like punching holes, straightening parts, or bending.

Dowel Pins

These little things can be found rolling around a number of toolboxes because they are quite versatile for workholding. If you need to hold a part at an odd orientation or if you need an orientation to be repeatable, dowel pins can be a lifesaver, especially when used with a sine vise.