-

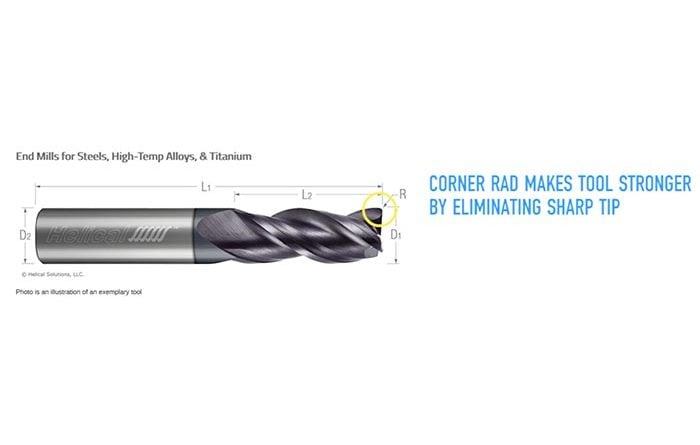

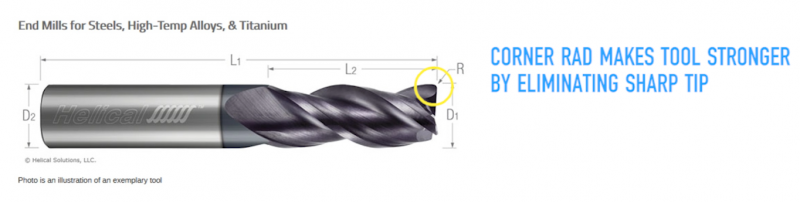

Tools with a small corner Radius

End mills with a small corner radius are some of our favorite tools! The small corner radius – usually 0.003” to 0.005” (0.07mm to 0.1mm) gets rid of the otherwise weakest point of a cutting tool: the sharp, unsupported corner! The radius is small enough to be insignificant for many machining operations – and, in fact, can have the benefit of leaving a small fillet in your part, reducing a possible stress-riser from a sharp inside corner.

Our “Tool 31” general use endmill is a ¼” LSC 3 flute endmill with a .003” corner radius that finds its way into nearly every one of our operations because of its durability and versatility.

http://www.lakeshorecarbide.com/14variablefluteendmillforaluminumzrn.aspx

-

Superfly & ShearHog

Insert tooling in general has some serious benefits – but the ShearHog & Superfly are two tools every Tormach user should have in their toolbox. The ShearHog is available in multiple sizes and modular options, while the Superfly has inserts for steel and aluminum (we prefer using the tool in aluminum). This adaptability makes them the perfect general use tool, keeping you from buying multiple solid-body tools for the job. And not only are they adaptable, but when they reach the end of their life all you need to do is replace the insert – not an entire tool. The ShearHog’s single-flute design gives it a large area for the chip to form and evacuate, making it much more tolerant of a minor CAM mistake that might cause chipwelding in a traditional endmill or rougher. With multiple insert options you can also use these tool with multiple materials, making them the perfect jack of all trades.

-

Twist Drills

Twist drills are a great way to maximize your machine’s MRR! Because the forces involved are vertical (in line with the spindle) you can take advantage of rigidity that you just can’t get out of a side-cutting endmill, resulting in some seriously impressive removal rates. Another benefit: HSS drill bits are CHEAP! It’s not at all uncommon for small or even home shops to have a full set of drill bits, making it easy to machine any size hole. Twist drills can also be easily resharpened, meaning one drill bit can last for years although they are cheap enough that anything under 3/8” is better to replace new.

-

High Feed Mills

The DiJet high feed mill is a fantastic tool and well suited for use with the Tormach. As a high feed tool, you take wide passes – often over 90% width of cut but very shall axial passes – sometimes as light as 0.003” (0.08mm) but at very high feedrates. We have achieved very respectable material removal rates on steel and stainless steel on the Tormach 1100 and 770 with good process reliability! When a high feed mill is cutting, the tool pressure is axial (meaning up and down, versus side-to-side) – this tends to benefit smaller machines like the Tormach. It also means you can use the longer Tormach arbor’s with a high feed mill with surprising rigidity for deep pockets and tall part features.

Written by: John Saunders of NYCCNC