Time-to-market is a term that every engineer knows all too well, and every budding entrepreneur will soon know if they are just entering the marketplace.

Rugged Video (http://www.ruggedvid.com) is a company that specializes in creating customized video capture solutions for harsh and unwieldy environments. The company’s niche is developing low volume systems specific to unique applications, like flight tours, jet boats, and even military applications.

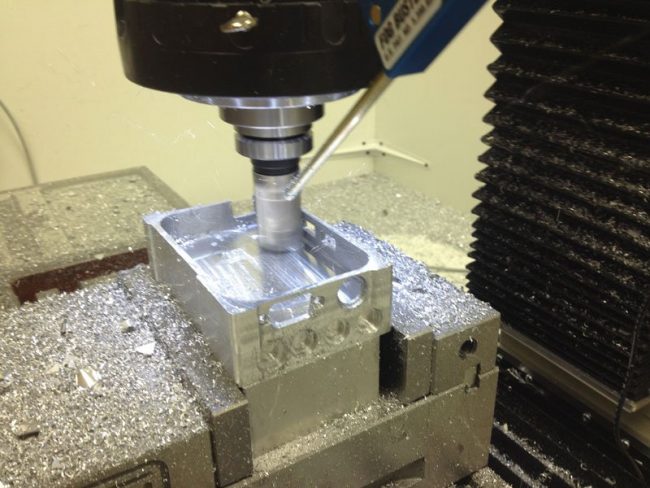

The company uses their PCNC 770 to manufacture enclosures, modify off-the-shelf enclosures, fabricate mounts and brackets, and engrave finished products, but they didn’t start out milling. At first, the company was utilizing 3D printing to create custom products. “With or needs to build custom products fast, 3D printing was the best available solution stat we recognized.

While 3D printing has its advantages we were limited to only making internal mounts, brackets, or prototypes since the finish and strength isn’t up to our standards,” Roy Dietsch, Co-Founder and CEO, explains. “However, 3D printing did open our eyes to the potential of rapid manufacturing. Moving to a CNC mill was the next logical step to start making real products on-site.”

For finished parts, Rugged Video used to outsource fabrication and production. “We had good vendors and attractive pricing, but the lead time was a huge impact on our business,” Dietsch says. “It used to take two to three weeks to get parts produced, another week for anodizing, and two more weeks for screen printing. Our production took five weeks, just for basic parts.”

When he was about to place a $5,000 order to mill parts, Dietsch decided, on a whim, to research low-cost, 3D printer-style CNC mills. “My searches turned up a bunch of hobby-style kits that seemed complicated and unreliable, and then I saw the Tormach,” Dietsch says.

He immediately recognized the Tormach’s ability to mill real parts with accuracy, and after spending the rest of the day researching the PCNC 770, he decided to purchase and bring production in-house.

“Outside of 3D printing we had no knowledge or experience in CNC or Milling. Luckily Tormach had a class starting in a couple days and squeezed us in. While my business partner was in the class I worked out the purchasing and got a lease set up with North Star Leasing,” Dietsch explains.

In just about any business, a five-week lead time is challenging in and of itself, but it presents a major issue when your business is reliant on customization and changing existing parts.

“All of our customers are unique and may want changes or supporting products to go along with the system.” With their Tormach, Rugged Video has been able to provide changes, supporting products, and customizations at a much lower cost to their customers, and typically with a lead time of just one to two days. “No other company in our industry can match this capability while using outside production services.”

Having a Tormach has allowed Rugged Video to launch new products faster and for less investment, since they not only use it for production, but also for easily adaptable iterations.

“We can identify production issues immediately and make changes between units, rather than between production runs,” Dietsch explains. Now the company even uses their PCNC 770 to create some of their product displays. Rugged Video saw their production costs drop and their time-to-market drastically increase, but they also credit Tormach as the “tow-rope up the learning curve” for their organization.

Dietsch explains, “Within two weeks of finding Tormach online, we were able to build our first part on our own machine. That would not have been possible with any other company.”