Machinists are familiar with spot drills–they’re stub length and have few or no flutes. These little drills are designed to be extremely rigid so that they can precisely spot a hole for a twist drill. Maximum meat in the shank keeps them on target. The goal is use the spot drill to make a little dimple in the work-piece that keeps the twist drill from walking so the hole winds up in the right place.

When Must I Use a Spot Drill?

Is a spot drill necessary every time an accurate hole is to be drilled? Its purpose is to ensure the hole is accurately located. The short spot drill is very rigid, and the spotting motion is unlikely to deflect. However, if you use a carbide drill, or a screw machine length drill, spotting is typically not needed. The carbide itself is rigid compared to HSS, so the drill will go where it is pointed. As a matter of fact, most manufacturers recommend against spotting either a carbide twist drill or an insertable drill, because it's easy to chip the carbide in the dimple. Screw machine length twist drills are much shorter, so they’re also less likely to flex. In general, you’ll save a lot of time if you can avoid spot drilling. Investing in a set of screw machine length twist drills is well worth it. I hardly ever use the jobber length bits. Sometimes you can't avoid using a jobber length drill, because the hole is too deep for a screw machine drill. In that case, you could spot drill to start the twist drill, or you could drill the shallow part of the hole with a screw machine length and then switch to the longer drill. Either way, you’re facing a tool change, so it’s six of one and half a dozen of the other.

Can I Use a Center Drill Instead of a Spot Drill?

A lot of machinists use center drills for spotting instead of true spotting drills. Center drills are intended to be used to create a hole suitable for a lathe center. They have a two-part tip that has a small pilot as well as the larger countersinking area of the bit. While center drills are cheaper than spot drills, they have some disadvantages:

- Delicate Tip: The small pilot tip is very delicate for example, and if it breaks, the drill will quit cutting. Not a happy thing if you’re running a job that involves spotting a lot of holes.

- Large Spot Angle: Another problem is the hole angle of a center drill is typically 60 degrees. When spotting, you want an angle that is larger than the twist drill’s angle if possible. The narrower the spot angle, the more near the outside diameter of the twist drill first contact will be. If the twist drill’s flutes aren’t perfectly sharpened, one will contact the spot hole before the other and the drill will try to deflect. This defeats the purpose of spot drilling and can result in a less accurate hole. The broader angle of a true spot drill means the tip of the twist drill cuts first, which makes for a more accurate hole.

- Temperature: Lastly, the web of a spot drill is typically thinner than a center drill, so it cuts more easily and with less heat.

Should I Use a Drill Chuck or Collet Chuck?

The choice of whether to use a drill chuck or collet chuck for a spot drill, or any other twist drill, is a divided one, because we’re optimizing two parameters and there is a different choice for each. For best accuracy, use a collet chuck for your spot drill and twist drills. Traditional drill chucks are less accurate and setscrew endmill holders are worse. However, for holding power, the drill chuck is the winner. Here’s why: The drill chuck concentrates its grip in three places. That grip is powerful, it often marrs the shank of the twist drill if the metal isn’t hard enough to resist. A collet, by contrast, spreads the force evenly 360 degrees around the shank, leading to less grip.The internal workings of drill chucks use wedges to create significant mechanical advantage when tightened. This leads to more gripping force than a collet achieves. In the end, I recommend using the collets for smaller drills, say 1/4″ and under, and the drill chucks for larger diameters that need more holding power.

Spot Drill Tips and Techniques

- When you spot the hole, let the spot drill dwell briefly at the bottom of the hole to ensure a smooth surface for the twist drill. G82 is typically a better cycle to use than G81 for that reason.

- Have you noticed the similarity in shape between a chamfer tool and a spot drill? Well, you can chamfer just fine with a spot drill. Give it a try, it might save you a slot in your toolchanger.

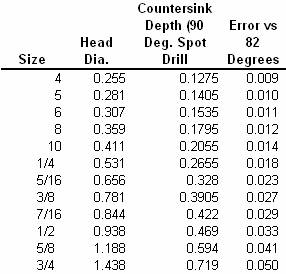

- While we’re on the subject of what else you can do with a Spot Drill, try counterboring for flat head cap screws. Rather than spot drill, drill, and then countersink, let’s kill two birds with one stone. The one fly in the ointment is the countersink spec for US flat head cap screws calls for an 82 degree countersink, whereas spot drills are most commonly 90 degrees. This immediately led me to produce the following little chart that lays it all out:

- First we have the size of the bolt, followed by the expected diameter of the head according to a manufacturer on the web.

- We can apply a little bit of geometery and realize that for a 90 degree angle, the cone of the cap screw is the hypoteneuse of a right isosceles triangle and 1/2 the head diameter is therefore the depth.

- Now a little trig and we can figure the error between the 82 degree countersink and our 90 degree spot drill’s countersinking. As you can see, it isn’t miniscule, but I doubt it is the end of the world either.

- Note that 82 degree spotting drills are also available, though in fewer sizes. They will be spot on with no error (sorry for the pun!).

- As far as I can see with a quick check, 82 degree and 90 degree spotting drills cost the same. You will have to buy a pretty good sized diameter spotting drill given that you need one at least equal to the head diameter of the flat head cap screw you end to spot and countersink with it. A 3/4″ diameter spotting drill is only good for 5/16″ and smaller screws. These spotting drills are not cheap, and cost about 2x what a countersink does, so you’d better be able to justify that with the time savings. I think I would learn to sharpen drill bits in short order if I was planning on doing very much of it. So, we can spot drill, counter-bore, and chamfer. But guess what, there’s more! You can also use your spot drill as a V-Bit engraver too!

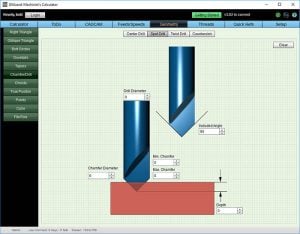

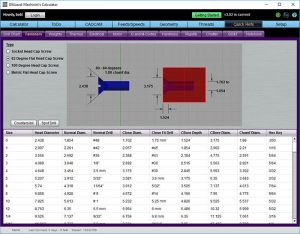

- If you’re going to do all these cool tricks with a spot drill, you’re going to need to do some geometry calculations. Fear not, our G-Wizard Calculator has some awesome tools to help:

The Calculator covers spot drills, center drills, counter bores, and more. Plus, there’s even a database of fastener counter-bore sizes:

What’s even more awesome is you get these useful calculators and a whole lot more entirely free and for life just by signing up for our free 30-day trial. That’s right–those features go right on working when the trial ends.