There is a lot that goes into taking an idea from concept to working part. Once you’ve developed a viable idea on a napkin sketch, you need to jump into design using a CAD program, then develop your toolpaths and tooling requirements in CAM, and then you need to actually machine the part with a CNC mill. But before you can move from software to an actual machine, you’ll need a post processor.

CNC Post Processor Basics

Simply explained, a post processor is a file that converts your CAM toolpaths into G-code for your specific machine. Many things can change in the G-code between different types of CNC machines, like supported canned cycles, decimal place location (digits required before and after the decimal), line numbering, and even certain G and M codes. Even if two different machines still use the standard Fanuc G-code (an industry staple), there are still nuances that can be affected in the G-code.

Post processors act as a translator from your CAM to creating G-code that is specific for your machine make and model. Even when two machines are very similar in size and capability, it is rare that the same post processor will work for two different make/model machines.

It’s best to think of the post processor as a communicator with the controller of your machine, not the machine itself. The machine takes direction from the controller, for example, PathPilot controls all of Tormach’s CNC machines. So, you are essentially creating G-code from your CAM work for the controller to read.

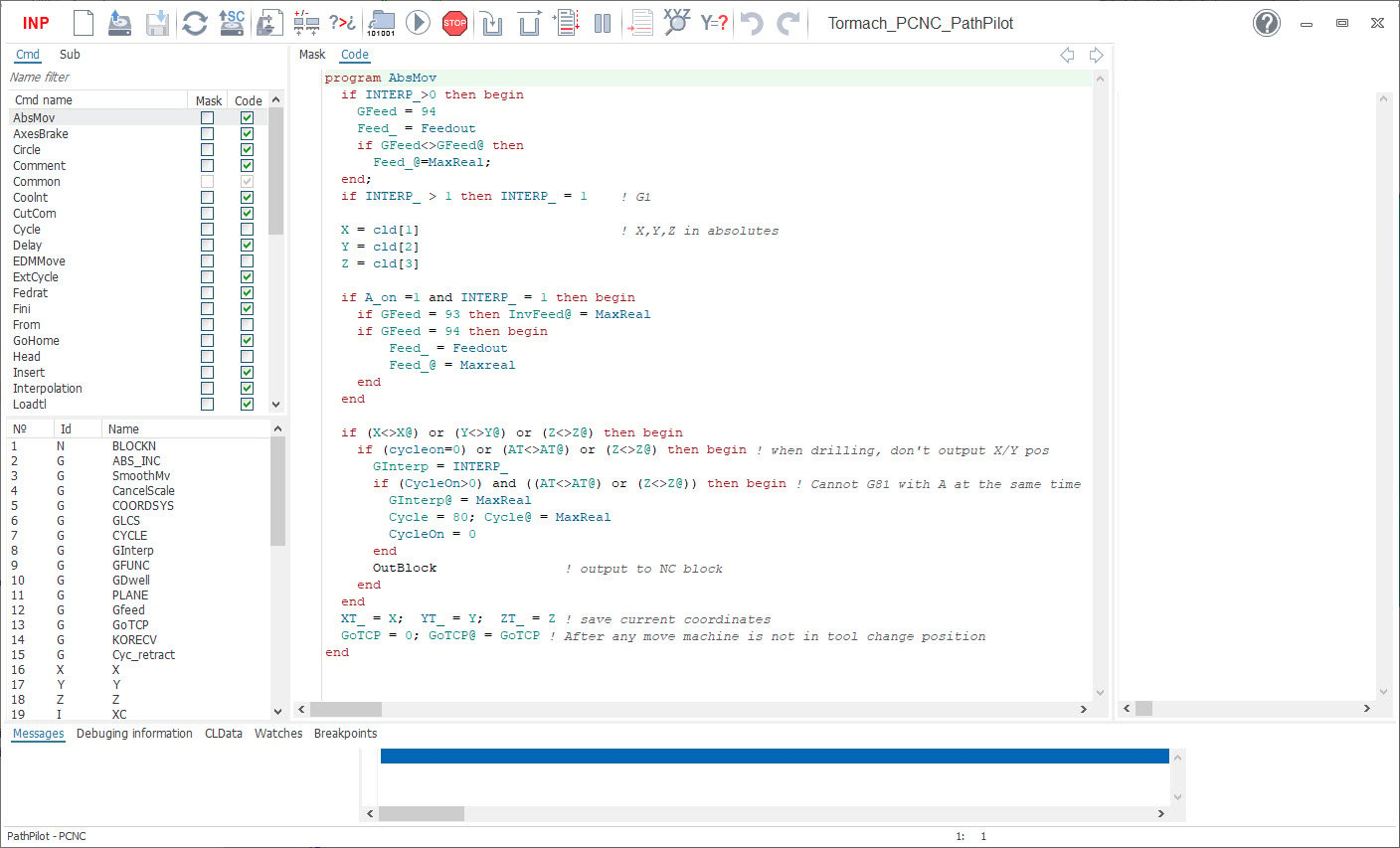

This is a Post Processor Generator that SprutCAM provides that shows how it creates an actual post processor. Screenshot provided courtesy of SprutCAM 15.

Homebrew CNC Post Processors

Many folks who are adept with programming and know their way around G-code develop their own homebrew post processors for their machines. Oftentimes, this is because they are building a homebrew CNC machine in the garage or basement. If your machine is custom made, it either needs to be built to similar specs as an OEM machine with a retrofit controller or a custom post processor needs to be created (sometimes both).

While it might be possible to develop a workable post processor for a homebrew machine, there are a lot of factors that need to be considered before you can call the G-code sound. Being cautious and testing thoroughly is key to using any sort of custom-made CNC post processor.

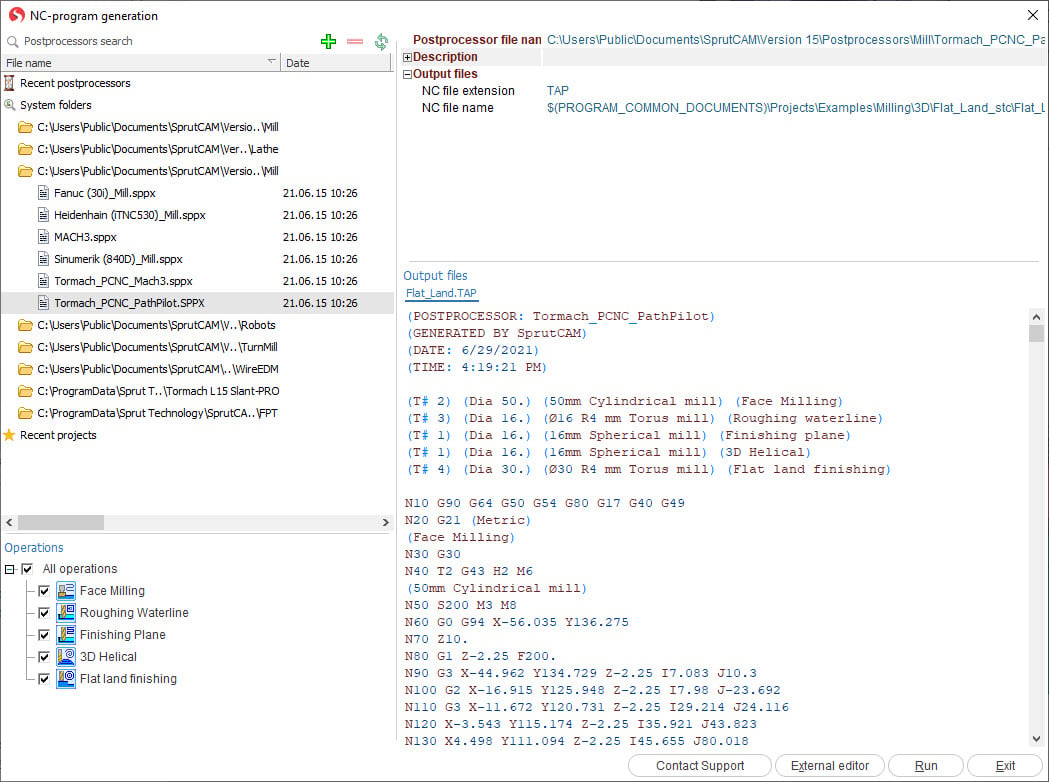

This is a post processing window in SprutCAM where you select the post processor (on the left) and then the actual creation of the G-code (on the right). Screenshot provided courtesy of SprutCAM 15

All CNC Post Processors Are Not Created Equal

While there are a large number of post processors out there, they aren’t all created equal. Some CNC users will modify an OEM post processor to try to get different tolerances or utilize a widget or add-on. Customizing can certainly be done, but without posting and a thorough understanding and analyzing of the G-code, it’s hard to know if it is usable.

At the end of the day, a verified post from a CAM software company or the machine manufacturer/vendor will be your best choice of post processor. Many CAM and CNC machine tool companies, like Tormach, provide these posts for various makes and models of machines for free on their websites.