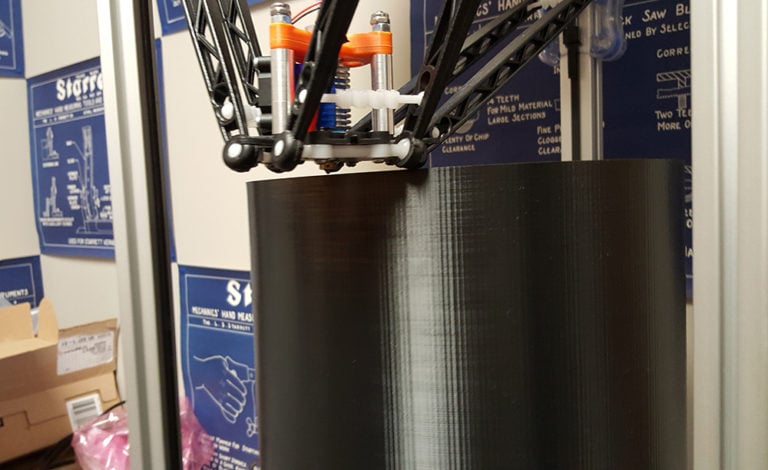

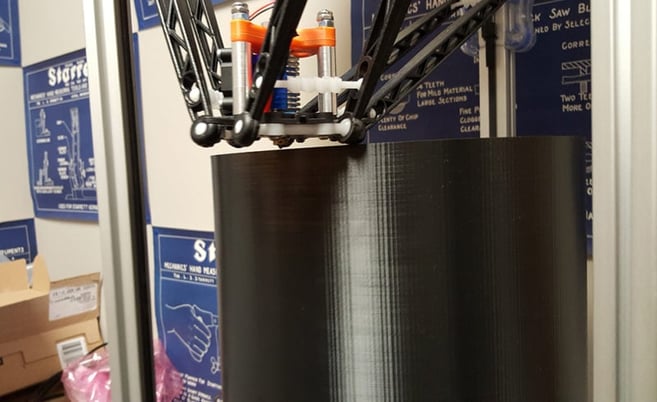

Fixturing and workholding is not only important for milling and machining, but it’s also vital for prototyping and QC processes. While 3D printing may not be as rigid or robust as other forms of workholding, these can be part of the advantage to 3D-printed fixturing.

Read: Workholding of the Month: Double-Sided Tape

3D printing is quite simple – depending on the printer, it can be as simple as click-and-go, once you have a CAD model. Because it is plastic, 3D-printed fixtures can easily be adjusted or tweaked.

3D printing your workholding may feel a little sacrilegious, but it can save time and money, depending on the type of fixturing you’re working on and the cuts you’re making.

Modern Machine Shop has an article about how 3D-printed vise jaws “provided an inexpensive solution to what otherwise might have been a costly workholding challenge for the shop.” We’ve even seen it used in production environments with Tormach’s Cast Iron Tombstone and a 4th axis.

Though some might consider 3D printing to be the enemy of traditional manufacturing, it definitely has a place in the world of CNC and workholding.