Our mission here at Tormach is to empower people who make things, and what better way to do that by sharing the stories of the Tormaker Community - people just like you.

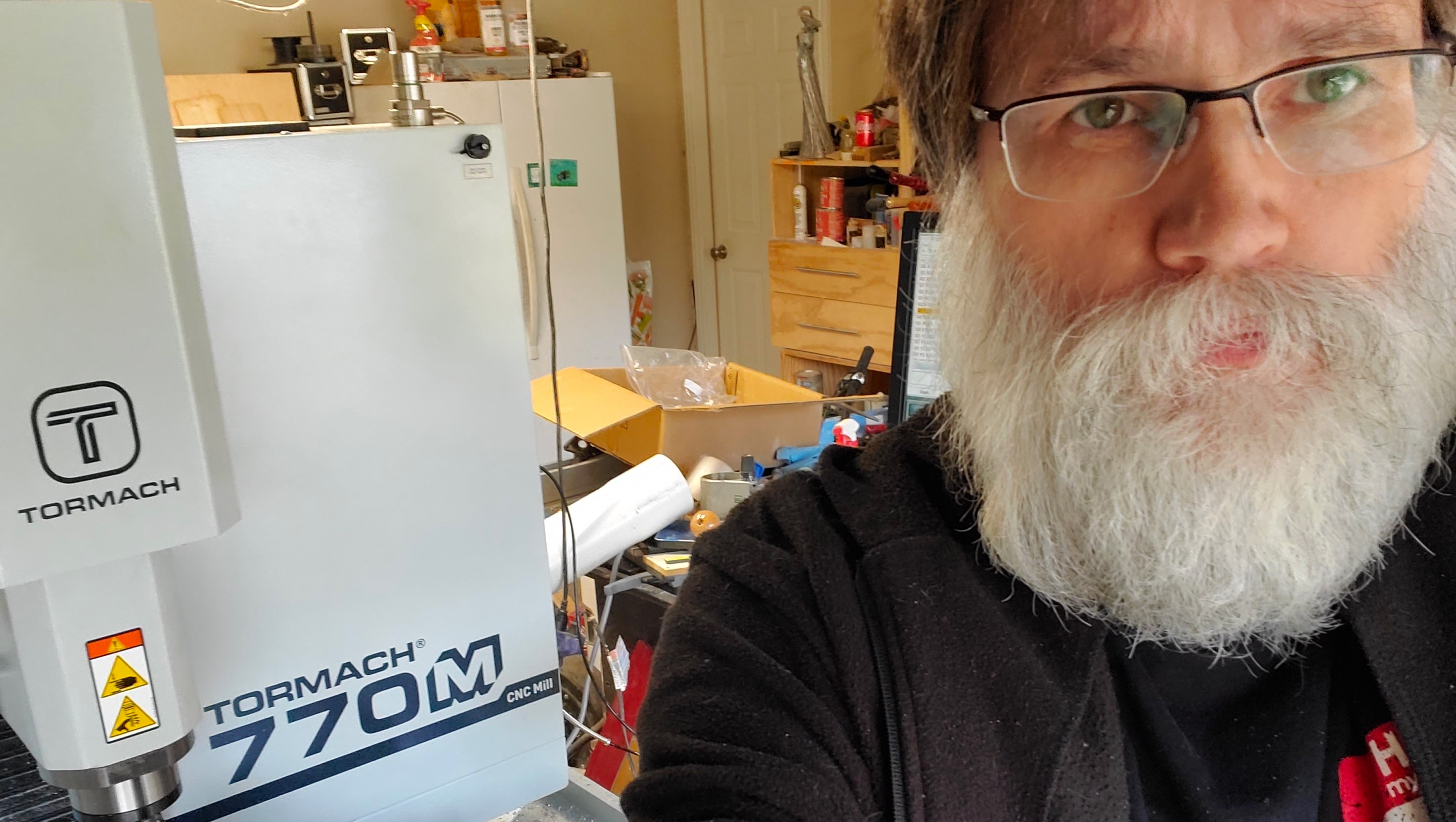

We're going to be catching up with our awesome Tormakers in this new blog series, and in today's post Adam Graham shares his experience of creating a new income source using the Tormach 770M.

Q: Tell us a bit about yourself, Adam!

A: I’m a third-generation oil industry machinist from rural Texas with a Masters degrees in Electrical Engineering and Software Engineering. I would say I’m fairly technical, as my day job is working as a Field Service Engineer for machines in the oil game. But with the oil industry being so volatile in the feast-or-famine way contracts work, I wanted to explore other potential income sources: CNC machining seemed a great solution.

Q: What machine do you have?

A: I have the Tormach 770M

Q: What do you make?

A: My business makes bespoke CNC machined parts for hobbyists, small businesses and large companies. I make small parts people find tricky to get hold of, just can’t make themselves, or need making specifically for a one-off job.

One reason a lot of clients use me is because I’m based in Texas. I can often make and ship parts to the US much faster (and cheaper) than they can get them from China or other overseas sources.

Q: Why did you choose a Tormach?

A: Two things: size and price. Because my garage was going to be my workshop, I needed something compact. And because this was a small business, I need something budget-friendly. Tormach solved both problems.

There was no way I could have fit one of the bigger machines in there, and at almost half the price of the alternative, picking the Tormach 770M was a no brainer. There weren’t many other machines of that calibre I could fit into my garage alongside my cars, woodworking cabinets, and other assorted hobby and household items. It was pretty cramped in there already.

Also, outsourcing to a machine shop is expensive. If I can make any parts I need on-site, it saves me money and I can see bigger margins on projects.

Q: What do you like about your Tormach?

A: The machine works way better than I expected. For example, my neighbour (an experienced engineer) was a bit skeptical the 770 could do a decent job for such a low price. But after trying it out, even he was impressed with its power and accuracy.

Looking back, I wish I’d gone for the full enclosure—it’s amazing just how far that thing can sling chips! But one of the great things about the 770 is that it’s modular, so I can build it up when required.

Q: What advice would you give to anyone thinking about a Tormach?

A: Tormach customer service was quick, fast, and efficient. I’d recommend them to anybody. Plus, if space is at a premium for you, but you still need a hard-working machine that will cut through metal with accuracy, then Tormach machines are perfect.

I made a few expensive mistakes early on, breaking a few end mills, but that was entirely user error. I can’t blame that on the machine. Although, it does show why the 770 is a great mill, because you can fail on it without it breaking the bank.

Oh, and I’d recommend anyone considering a Tormach to go online and check out two experienced CNC guys in the shape of John Saunders and Titan Gilroy. Both have great videos on their social accounts showing you just what to expect from a Tormach. They’re honest, and pull no punches.